Boron Nitride Electrode insulator for Ion Implanter

What is Boron Nitride?

Hexagonal boron nitride (h-BN) ceramic has a microstructure similar to graphite. It is manufactured by hot pressing boron nitride powders at temperatures up to 2000 °C and high pressure. The maximum blank size is 500 × 500 × 200 mm, and it can be further machined into complex shapes.

Why Can Boron Nitride Ceramics Be Used in Ion Implanters?

Ion implantation is a key process in semiconductor manufacturing, where wafers are doped with foreign atoms to modify material properties such as conductivity and crystal structure.

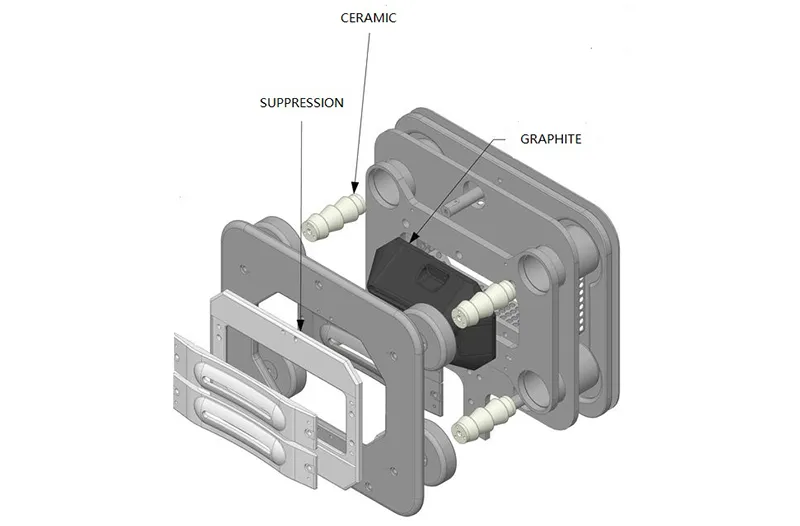

The high-current extraction electrode is the core of an ion implanter system. It must withstand temperatures up to 1400 °C, strong electromagnetic fields, aggressive process gases, and high mechanical forces.

Therefore, components made from boron nitride insulator ceramics help ensure that this process remains efficient, precise, and free of impurities.

The unique combination of exceptional thermal, physical, and chemical characteristics of INNOVACERA’s Boron Nitride ceramics makes them ideal for addressing critical challenges in insulator applications.

Boron Nitride Material Advantages

Non-Wetting

High Electrical Resistivity

High Thermal Conductivity

Excellent Machinability

Good Chemical Inertness

High-Temperature Resistance

High Dielectric Breakdown Strength

Excellent Thermal Shock Resistance

Excellent Lubricating Properties (Low Coefficient of Friction)

INNOVACERA Boron Nitride Ceramics Grades

Learn more about our binder-bonded grades HB, with over 90% BN, our highest purity (>99.7% BN) grade UHB, and our composite grades BMS, BMA, BSC, BMZ, BAN and BSN.

| Properties | Unit | UHB | HB | BC | BMS | BMA | BSC | BMZ | BAN | BSN |

| Main Composition | – | BN>99.7% | BN>99% | BN>97.5% | BN+SiO2 | BN+Al2O3 | BN+SiC | BN+ZrO2 | BN+AlN | BN+Si3N4 |

| Color | – | White | White | White | White Graphite | White Graphite | Greyish-Green | White Graphite | Greyish-Green | Gray Black |

| Density | g/cm3 | 1.6 | 2 | 2.0~2.1 | 2.2~2.3 | 2.25~2.35 | 2.4~2.5 | 2.8~2.9 | 2.8~2.9 | 2.2~2.3 |

| Three-Point Bending Strength | MPa | 18 | 35 | 35 | 65 | 65 | 80 | 90 | 90 | / |

| Compressive Strength | MPa | 45 | 85 | 70 | 145 | 145 | 175 | 220 | 220 | 400~500 |

| Thermal Conductivity | W/(m·k) | 35 | 40 | 32 | 35 | 35 | 45 | 30 | 85 | 20~22 |

| Thermal Expansion Coefficient (20~1000°C) | 10-6/K | 1.5 | 1.8 | 1.6 | 2 | 2 | 2.8 | 3.5 | 2.8 | / |

| Max Using Temperature In Atmosphere In Inactive Gas In High Vacuum (Long Time) | °C | 900 2100 1800 | 900 2100 1800 | 900 2100 1900 | 900 1750 1750 | 900 1750 1750 | 900 1800 1800 | 900 1800 1800 | 900 1750 1750 | 900 1750 1700 |

| Room Temperature Electric Resistivity | Ω·cm | >1014 | >1014 | >1013 | >1013 | >1013 | >1012 | >1012 | >1013 | / |

| Typical Application | – | Nitrides Sintering | High Temperature Furance | High Temperature Furance | Powder Metallurgy | Powder Metallurgy | Powder Metallurgy | Metal Casting | Powder Metallurgy | Metal Casting |

Packaging of Boron Nitride Components

Given its fragile nature, boron nitride is typically vacuum-sealed in plastic bags, cushioned with thick foam, and packed in cartons to prevent damage during transportation. Special packaging arrangements can be provided upon request.

Contact INNOVACERA

INNOVACERA offers a wide range of boron nitride materials and solutions. If you are looking for a boron nitride insulator solution for your application, please contact us to learn more about our full product range and how we can support your needs.

Comments

Post a Comment