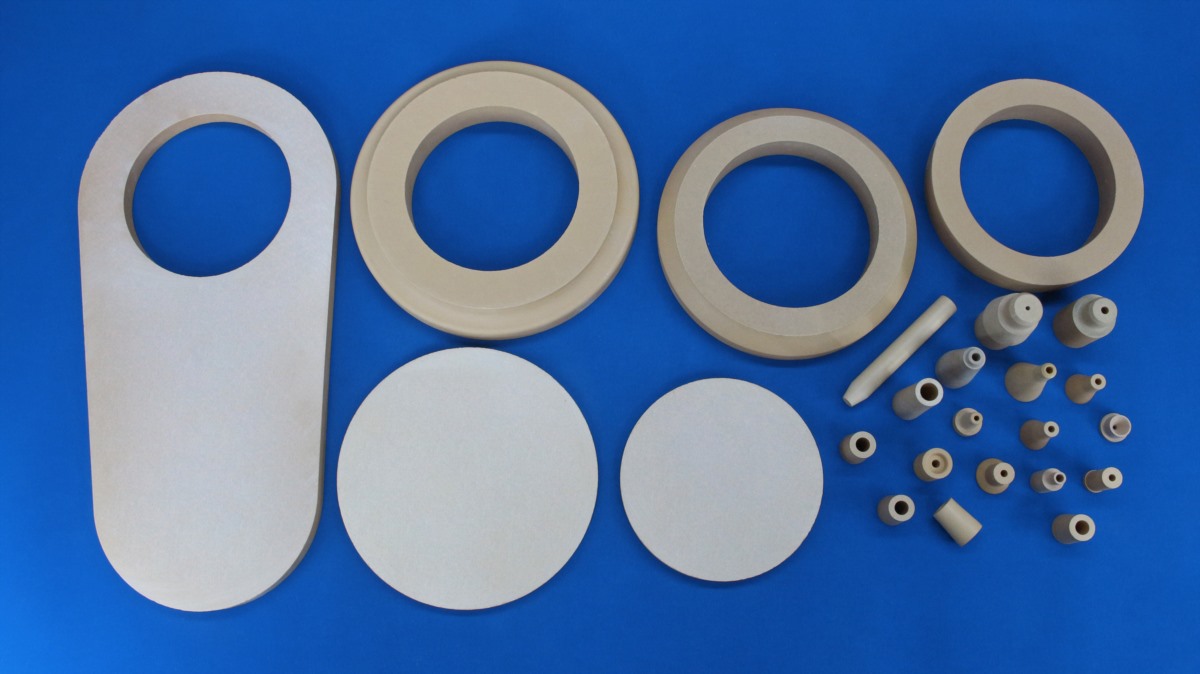

Mg-PSZ Ceramic Parts For Tundish In the Powder Metallurgy Process

Magnesium-zirconium ceramic parts, the main components of tundishes in the steel and metallurgical industry

The tundish is mainly used in the steel metallurgical process as a key component of the continuous casting process. Its primary function is to store and distribute molten steel, ensuring a continuous and stable flow from the ladle to the mold.

Main Components of a Tundish

Tundish Body — The main structure that holds molten steel, typically consisting of a refractory lining and a steel shell.

Lining — Includes the working layer in direct contact with molten steel and the permanent layer for thermal insulation. Commonly made from refractory bricks, castables, or spray coatings.

Stopper Rod — A critical part for controlling the molten steel flow rate and regulating the steel level in the crystallizer.

Submerged Entry Nozzle (SEN) — Introduces molten steel into the crystallizer while preventing oxidation and splashing.

Sliding Gate System — Precisely controls the molten steel flow rate, consisting of upper and lower slides and a drive mechanism.

Impact Pad — Reduces impact force during molten steel injection and prevents lining erosion.

Weirs & Dams — Optimize the molten steel flow path and promote the flotation and separation of inclusions.

Tundish Flux / Powder — Prevents oxidation of molten steel and helps retain heat.

Magnesium-Stabilized Zirconia (Mg-PSZ) Ceramic Parts in Tundishes

Magnesium oxide partially stabilized zirconia (Mg-PSZ) ceramics offer excellent corrosion resistance, outstanding thermal shock resistance, and stability at high temperatures, making them suitable for the following critical tundish components:

Shroud Nozzle (SEN) — Requires resistance to molten steel erosion and thermal shock. Mg-PSZ significantly extends service life.

Stopper Rod Tip — Directly contacts molten steel and must be resistant to high-temperature erosion. Mg-PSZ enhances corrosion resistance.

Sliding Gate Plates — Mg-PSZ provides superior wear and thermal shock resistance against molten steel erosion and mechanical wear.

Impact Pads — Mg-PSZ is effective in high-erosion areas, extending operational life.

Advantages of Magnesium-Stabilized Zirconia (Mg-PSZ) Ceramics

- High-temperature resistance (up to 2000 °C)

- Excellent thermal shock resistance (withstanding severe temperature fluctuations during continuous casting)

- Superior resistance to molten steel and slag erosion (superior to alumina and mullite)

These unique features make Mg-PSZ ceramics an ideal material for key refractory components in tundishes, particularly in the continuous casting of high-end steel grades.

Comments

Post a Comment