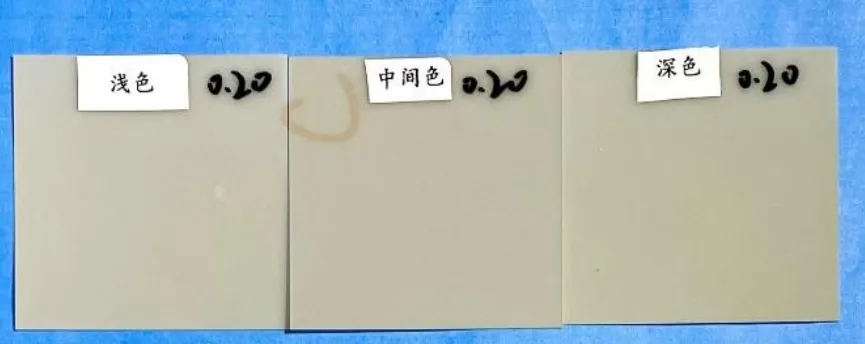

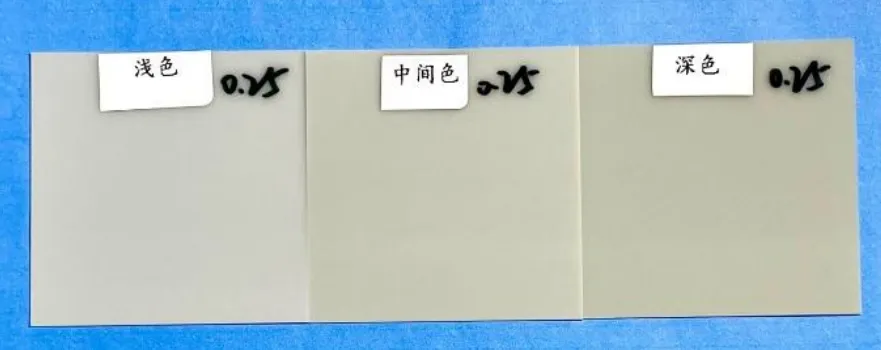

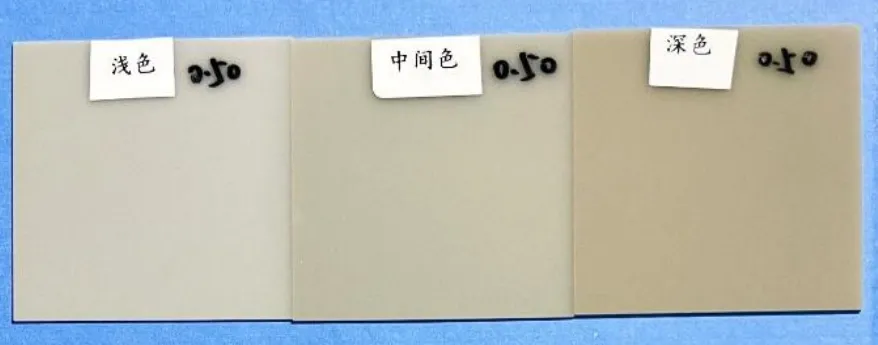

Analysis of the Causes of Chromatic Aberration in AlN Substrate Ceramics

The causes of color difference in AlN ceramics are related to raw material preparation, processing technology (sintering temperature fluctuation, protective atmosphere), microstructure, and environmental factors. The following provides a comprehensive analysis based on related research:

1. Surface Color Change Due to Oxidation Behavior

AlN ceramics easily react with oxygen at high temperatures to form aluminum oxide (Al₂O₃). The thickness and structure of the oxide layer significantly affect the surface color.

Oxidation kinetics: Differential thermal analysis shows that the mass change of AlN during variable temperature oxidation is related to the degree of oxidation. Different stages of the oxidation reaction may be accompanied by gradual changes in color.

2. Influence of Preparation Process and Raw Material Purity

Difference in synthesis methods: The hydrothermal–carbothermal synthesis method can reduce impurity introduction by regulating precursor homogeneity (e.g., γ-AlOOH@C core–shell structure). However, if the raw materials (e.g., aluminum nitrate, sucrose) are of insufficient purity, residual impurities (e.g., Fe, Si) will alter the color properties of the ceramics.

Protective atmosphere in the furnace: Aluminum nitride ceramics sintering is protected by N₂ gas to inhibit the volatilization of AlN and prevent contamination by impurities. On the surface exposed to N₂ protection, AlN ceramics tend to appear lighter in color, contributing to color differences.

3. Microstructure and Defects

Grain and pore distribution: The coexistence of fibrous polymorphic AlN (e.g., 27R, 21R structures) enhances the mechanical properties of the material. However, anisotropy in the microstructure can lead to differences in light scattering, resulting in chromatic aberration.

Surface morphology evolution: During high-temperature annealing, thermally etched pits and polygonal pits form at step edges. These features alter light reflection. As bevel angles increase, pits merge to form V-shaped edges, further affecting color uniformity.

4. Admixture and Impurity Effects

Additive effects: Y₂O₃ and SiO₂ are commonly used to densify AlN ceramics and promote fibrous polymorph growth. However, these dopants may introduce trace coloration (e.g., Y imparting a light yellow tint).

Impurity contamination: Metal ions (e.g., Fe³⁺, Cr³⁺) introduced from raw materials or processes can absorb specific wavelengths of light through electronic transitions, resulting in color deviations.

5. Test Conditions and Observation Environment

Light source and observation angle: The phenomenon of metamerism may lead to differences in perceived color under different lighting. For example, the color difference observed under showroom lighting versus natural light needs to be verified using multiple light sources (e.g., with assistance from a cell phone flashlight).

Instrumental measurement errors: Variations in the geometric systems of colorimeters and spectrophotometers may affect data consistency. Therefore, measurements should be complemented by visual assessment to reduce misjudgment.

Summary and Recommendations

The color difference of AlN ceramics results from the coupling of multiple factors. Control measures include:

Process Optimization: Precisely regulate sintering temperature, time, and atmosphere (e.g., inert gas protection) to reduce oxidation and impurity introduction.

Raw Material Selection: Use high-purity raw materials and establish pigment/dopant databases to ensure batch consistency.

Surface Treatment: Improve surface uniformity and reduce light scattering through polishing or coating techniques.

Standardized Testing: Combine instrumental measurements (e.g., colorimeter) with visual evaluation under multiple light sources to establish strict color tolerance standards (e.g., ΔE ≤ 1).

Comments

Post a Comment