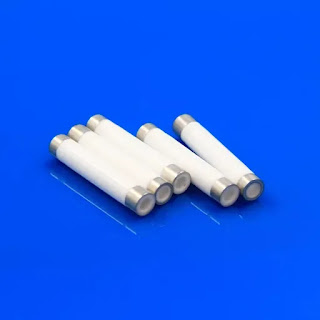

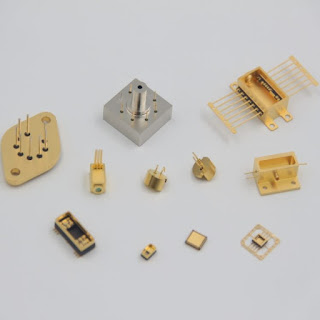

Glass-To-Metal Seals and Feedthroughs

Glass-To-Metal Seals and Feedthroughs InSealing specializes in Glass-To-Metal Seals and Feedthroughs, where glass is heated to a molten state and then wetted to the metal, creating a tight bond while carefully controlling the thermal expansion of both materials to prevent breakage. InSealing offers Glass-To-Metal Seals and Feedthroughs . Glass is heated to a molten state then wetted to the metal, forming a tight bond. The thermal expansion of the glass and the metal are carefully measured and controlled to prevent breakage. InSealing offers not only electrical feedthroughs, the most common type we make, but also RF and microwave feedthroughs. Materials: Body materials: Cold rolled steels, Stainless steel, Inconel, etc. Glass Materials: Soda lime, Lead silicate, etc. Electrodes Material: Alloy 52, Copper Cored 52 Alloy, Alloy 42, etc. Typically Compression Seals withstand temperatures ranging from -250°C to 400°C. Allowable operating temperatures would be from -60°C to 200°C under th