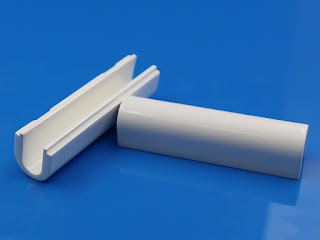

Oxygen Sensor Element

Source: https://www.innovacera.com/product/oxygen-sensor-element Tag: Innovacera ceramic heating element is suitable for use in Bosch / Denso / Delphi / NTK&NGK Oxygen Lambda Sensor, Oxygen sensors are designed to monitor the amount of oxygen that's in the car's exhaust stream, while ceramic heater plays an important role in the O2 sensor. During heating, zirconia conducts oxygen ions, a characteristic that allows oxygen ions to flow from the high O2 concentration of air to the low O2 concentration on the exhaust side of the ceramic. Innovacera produces ceramic heating rod and planar ceramic heater, the rod shape is used for thimble oxygen sensor and planar ceramic heater is used for planar oxygen sensor. Thimble oxygen sensor cutaway: Planar oxygen sensor cutaway: Planar ceramic heater oxygen sensors have the below characteristics: Quick ignition time Good insulation performance Strong resistance to high temperature and poisoning Long lifetime Many types such as pump curre