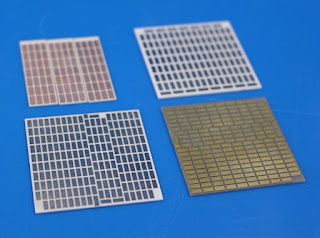

Introduction for Our New Developed AIN Heaters

Source: https://www.innovacera.com/news/new-developed-ain-heaters.html The special heaters of Innovacera are flexible in design and can meet different applications requiring different construction methods. This flexibility allows the heater to be configured to a variety of shapes and sizes depending on the application. We have developed AIN heaters which are using highly heat-conductive AIN, these heaters deliver outstanding temperature consistency through the uniform sintering of resistance-heating elements and significantly reduce metallic contamination and impurities. The advantage of the AIN heaters: 1. Thermal conductivity equivalent to aluminium for fast and uniform thermal response 2. Watt density higher than any metal or ceramic heater technology for concentrated heat in a small area 3. Integrated RTD sensor for optimum heater temperature control 4. Dielectric strength eliminates the need for magnesium oxide insulation(MgO) layer used in metal heaters 5. Heater temperature up