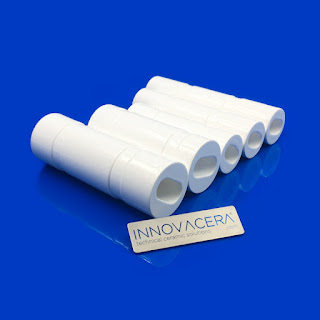

Alumina Ceramic Thermocouple Protection Sleeve

Insert Way: When the insulation tube is used, the two poles of a temperature measuring element are inserted into different holes in the same direction. The temperature measuring element is sleeved in a protection tube to be protected after being arranged. Stock size of insulation tube: outer diameter 1mm to 12mm, with single orifice, double, four or more orifices in diameter 0.5mm minimal, maximal length 1600mm, all dimensions can be customized according to user demands. Technical parameters: Maximum service temperature: 1800℃ Compressive strength:2500 Mpa Volume density: 3.95g/cm3 Bending strength :400Mpa Fracture toughness:5-7 Mohs hardness: 9 Application: The insulation tube is made from a material with good insulation property, and is mainly used for separating different polarity items of a temperature measuring element, so that the phenomenon that the two poles interfere with each other or are in contact with each other to cause a short circuit is avoided, and temperature is acc

.jpg)