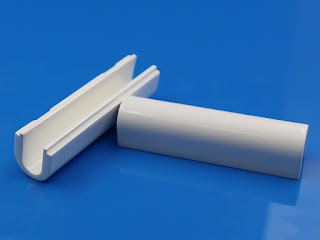

Ceramic Reflector

Source: https://www.innovacera.com/product/ceramic-reflector Innovacera manufactures custom and standard ceramic reflector designs for flash lamps, continuous-wave lasers, diode-pumped lasers, and cosmetic surgery markets. Ceramic Reflector is made by high purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity. Ceramic Reflector material properties: Bulk density (fired), Mg/m3:3.1 Color: White Porosity (apparent), % nominal: 22 Flexural strength (ASTM C1161, 3-point), MPa: 170 Thermal expansion coefficient 200-500C, 10-6/C 7.9 200-1000C, 10-6/C 9.0 Ceramic Reflector features: Compared to metal reflectors, ceramic units offer higher reflectivity and therefore enhanced laser power Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk reflectivity Resists chemical attack Controlled porosity Has high strength