What Technology Enables Ceramics and Metals to Achieve A "Strong Combination"?

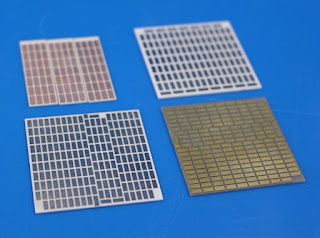

Source: https://www.innovacera.com/news/ceramics-and-metals-to-achieve.html Ceramics are often referred to as inorganic non-metallic materials. It can be seen that people directly position ceramics on the opposite side of metal. After all, the performance of the two is worlds apart. But the advantages of the two are too prominent, so in many cases, it is necessary to combine ceramics and metals, each showing their strengths, so the technology-ceramic metalization technology was born. Especially with the advent of the 5G era, the power of semiconductor chips continues to increase. The development trend of lightness and high integration is becoming more and more obvious, and the importance of heat dissipation is also becoming more and more prominent. This undoubtedly puts more stringent requirements on package heat dissipation materials. In the packaging structure of power electronic components, the packaging substrate serves as a key link for connecting the upper and lower parts ...