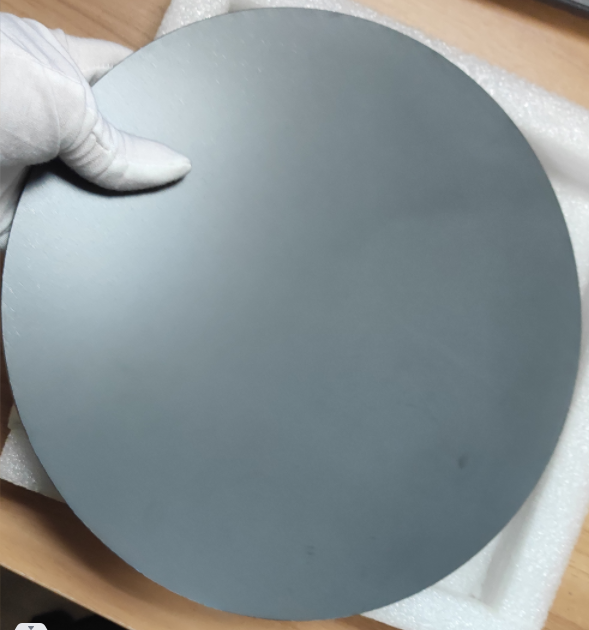

Hot pressing Aluminum Nitride Used For Semiconductor Fabrication Equipments

Hot pressing Aluminum Nitride (AlN) ceramics are used as wafer heating plates and wafer holding electrostatic chucks in semiconductor fabrication equipments.

Advantages of Hot pressing ALN Aluminum nitride ceramic:

– High purity

– Electrical insulator

– High thermal conductivity

– Critical thermal management material

– Reduced Particulate Generation

– Corrosion/Erosion Resistance

– Controlled Electrical Properties

Properties:

| Property | Units | Value |

| Flexural Strength, MOR (20 °C) | MPa | 300-460 |

| Fracture Toughness | MPa m1/2 | 2.75-6.0 |

| Thermal Conductivity (20 °C) | W/m K | 100-170 |

| Coefficient of Thermal Expansion | 1 x 10-6/°C | 3.3-5.5 |

| Maximum Use Temperature | °C | 800 |

| Dielectric Strength (6.35mm) | ac-kV/mm | 16.0-19.7 |

| Dielectric Loss | 1MHz, 25 °C | 1 x 10-4 to 5 x 10-4 |

| Volume Resistivity (25°C) | Ω-cm | 1013 to 1014 |

Typical Application:

– Cover plates and MRI equipment(Magnetic Resonance Imaging)

– High-power detectors, plasma generators, military radios

– Electrostatic chucks and heating plates for semiconductors and integrated circuits

– Infrared and microwave window material

Hot Pressing Aluminum Nitride Wafer

Comments

Post a Comment