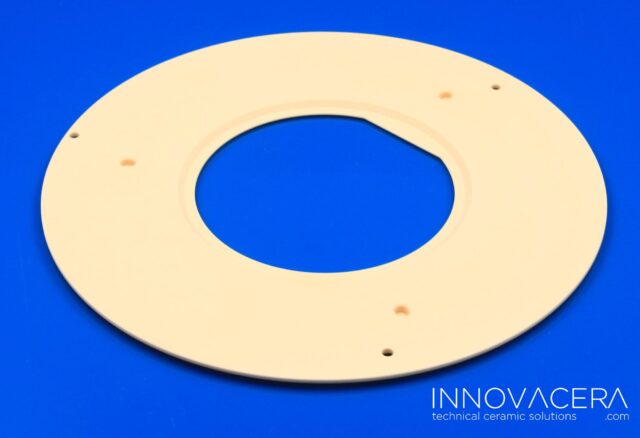

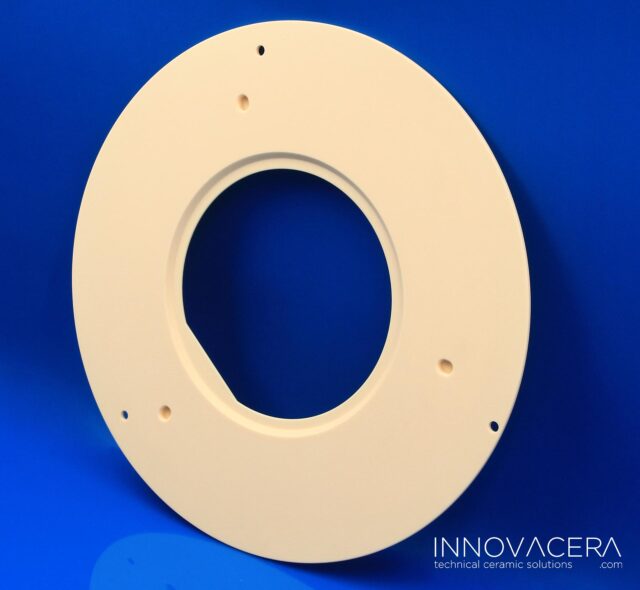

Semiconductor Wafer Carrier Alumina Disk and Ceramic Edge Ring

Semiconductor Wafer Carrier Alumina Disk and Ceramic Edge Ring

High precision ceramic components improve yield management for semiconductor wafer processing. Innovacera ceramic components provide precise dimensional stability, ultra-flatness and smoothness, and vacuum holding of wafers during inspection and processing. Low-surface-contact configurations minimize risk of back-side particles negatively affecting wafer geometry for precision applications.

The main features of high precision ceramic parts:

1. Wear and abrasion resistance: Alumina is a tough technical ceramic with very good wear resistance.

2. High precision dimensions with tightening tolerance, it easier to get a perfect fitting relationship.

3. Chemical inertness, resistant to most of the strong acids and alkalis.

4. High-temperature ability: withstand up to 1600°C in oxidizing and reducing atmospheres.

5. Great mechanical properties, hardness, compressive, and flexural strength are much higher in stainless steel.

6. Electrical insulation: The insulation breakdown is 20KV at least.

7. Protective atmospheres or high vacuum at high temperatures to eliminate contamination or impurity.

8. Chemical corrosion resistance under high temperatures, even with strong acid or alkali.

9. Low material cost in high-level applications than other technical ceramics.

Comments

Post a Comment