Boron Nitride Ceramic Revolutionizing PVD Coating Technology

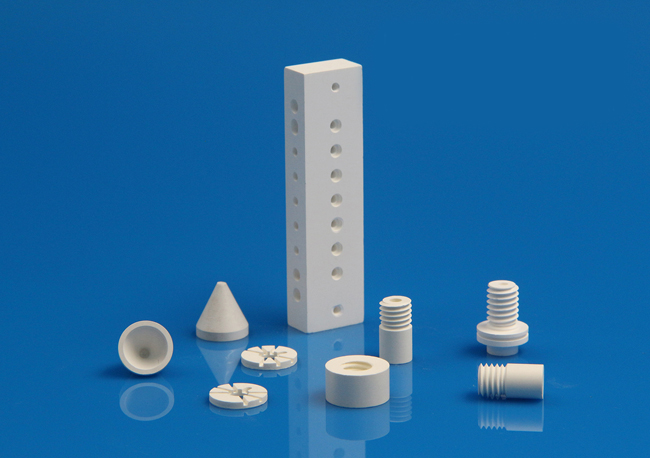

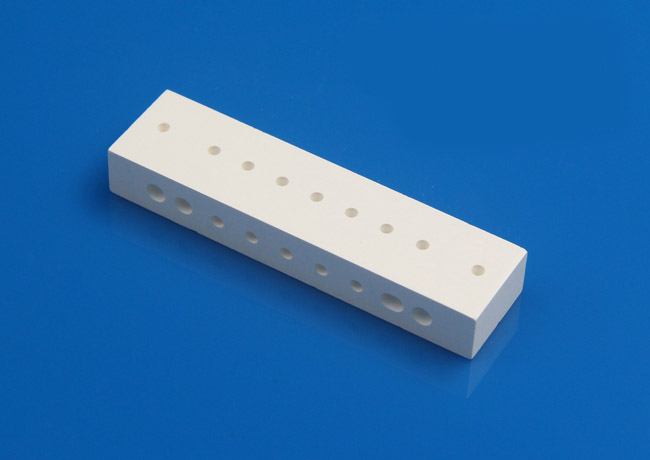

Boron Nitride ceramic (BN) with various applications, stands out as a versatile and high-performance compound in advanced materials. From its low thermal expansion excellent heat resistance outstanding electrical insulation and high wet resistance to molten metals, boron nitride has found its way into various industries, including electronics, high-temperature furnace construction, ceramic manufacturing, semiconductor industry, aerospace, and now the realm of Physical Vapor Deposition (PVD) coating technology.

PVD coating is a process used to produce thin films or coatings on various substrates by evaporating and condensing a material in a vacuum environment. This technique is widely employed in automotive and optics industries, where thin films of metals, ceramics, or other materials are deposited onto surfaces to enhance their properties such as wear resistance, corrosion resistance, or aesthetic appeal.

Boron Nitride Ceramic has emerged as a game-changer in the realm of PVD coating, offering several advantages over traditional coating materials:

High Thermal Stability

Chemical Inertness

Excellent Lubricating Properties

Uniform Coating Deposition

Enhanced Safety and Environmental Sustainability: Unlike some traditional coating materials that may pose health or environmental risks, BN ceramic is non-toxic and environmentally friendly. Its use in PVD coating machines contributes to safer working environments for operators and reduces the environmental impact of coating processes. Furthermore, the durability and longevity of BN ceramic components reduce the frequency of maintenance and replacement, further enhancing the sustainability of PVD coating operations.

Boron Nitride Ceramic represents a significant advancement in the field of PVD coating technology, offering unparalleled thermal stability, chemical inertness, lubricating properties, and coating uniformity. By using boron nitride ceramic components in PVD coating machines, manufacturers can enhance operational efficiency, improve coating quality, and ensure the safety and sustainability of their processes. As demand for high-performance thin films continues to grow across various industries, boron nitride ceramic is poised to play a pivotal role in shaping the future of PVD coating technology.

Comments

Post a Comment