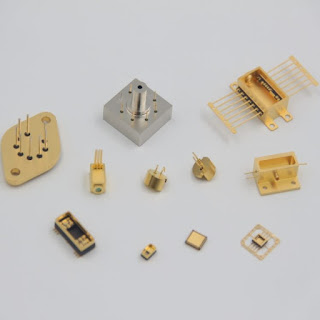

Glass-To-Metal Seals and Feedthroughs

Glass-To-Metal Seals and Feedthroughs

InSealing specializes in Glass-To-Metal Seals and Feedthroughs, where glass is heated to a molten state and then wetted to the metal, creating a tight bond while carefully controlling the thermal expansion of both materials to prevent breakage.

InSealing offers Glass-To-Metal Seals and Feedthroughs.

- Glass is heated to a molten state then wetted to the metal, forming a tight bond.

- The thermal expansion of the glass and the metal are carefully measured and controlled to prevent breakage.

- InSealing offers not only electrical feedthroughs, the most common type we make, but also RF and microwave feedthroughs.

Materials:

- Body materials: Cold rolled steels, Stainless steel, Inconel, etc.

- Glass Materials: Soda lime, Lead silicate, etc.

- Electrodes Material: Alloy 52, Copper Cored 52 Alloy, Alloy 42, etc.

- Typically Compression Seals withstand temperatures ranging from -250°C to 400°C. Allowable operating temperatures would be from -60°C to 200°C under thermal cycling and shock.

Properties:

- Hermeticity: up to 1 x 10-9 atm cc/sec He

- Insulation resistance: typically exceeds 1 GΩ @ 100 VDC

- Mechanical strength can withstand 20,000 psi with proper design for use in high-pressure applications

- Dielectric: can withstand voltage depending on joint geometry and glass material selected. Below are some typical glass values

– Barium Alkali: 6.3

– Brososilicate: 4.9

– Soda Lime: 7.2

Plating:

- Gold Plating

- Silver Plating

- Electrolytic and Electroless Ni Plating

- Tin Plating

Comments

Post a Comment