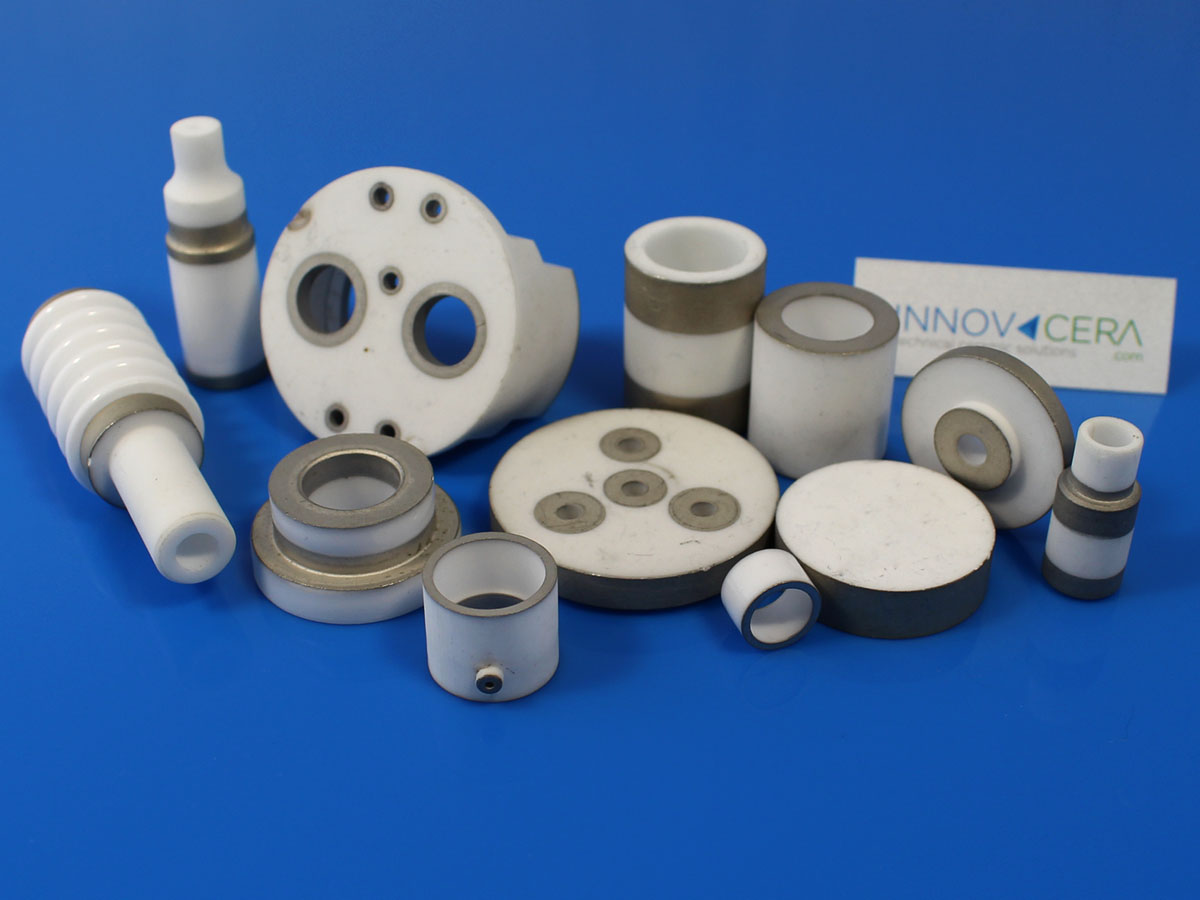

Metallization of alumina and application

Source: https://www.innovacera.com/news/metallization-of-alumina.html

With the development of modern technology, more and more new materials used in various fields. Technical ceramics are one of them, and the most popular is alumina(Al2O3).

However, since ceramic is an insulating material, it cannot be directly connected with other components. We wanted to make it even more useful, so ceramic metallization was born out of operations.

Ceramic metallization is to firmly adhere to a layer of metal film on the ceramic surface. The main role is to realize the welding between ceramic and metal. A more advanced application is to form a circuit on the surface of the ceramic, which can not only be welded but also be used as a wire to transmit current.

Nowadays, there are many methods used to manufacture metallization, including molybdenum manganese (Mo-Mn), Gold plating, Copper plating, LAP, etc.

Innovacera metallization of alumina main material is 95% alumina and 99% alumina. We will perform ceramic surface treatment before metallization to ensure the quality of metallized products.

Therefore, there will be advantages such as precision scale, small warpage, strong bonding between metal and ceramic, dense joints between metal and ceramic, and excellent heat dissipation.

So, Alumina ceramics widely used in LED heat dissipation substrates, ceramic packages, electronic circuit substrates, and electronic and electrical components.

With the development of modern technology, more and more new materials used in various fields. Technical ceramics are one of them, and the most popular is alumina(Al2O3).

However, since ceramic is an insulating material, it cannot be directly connected with other components. We wanted to make it even more useful, so ceramic metallization was born out of operations.

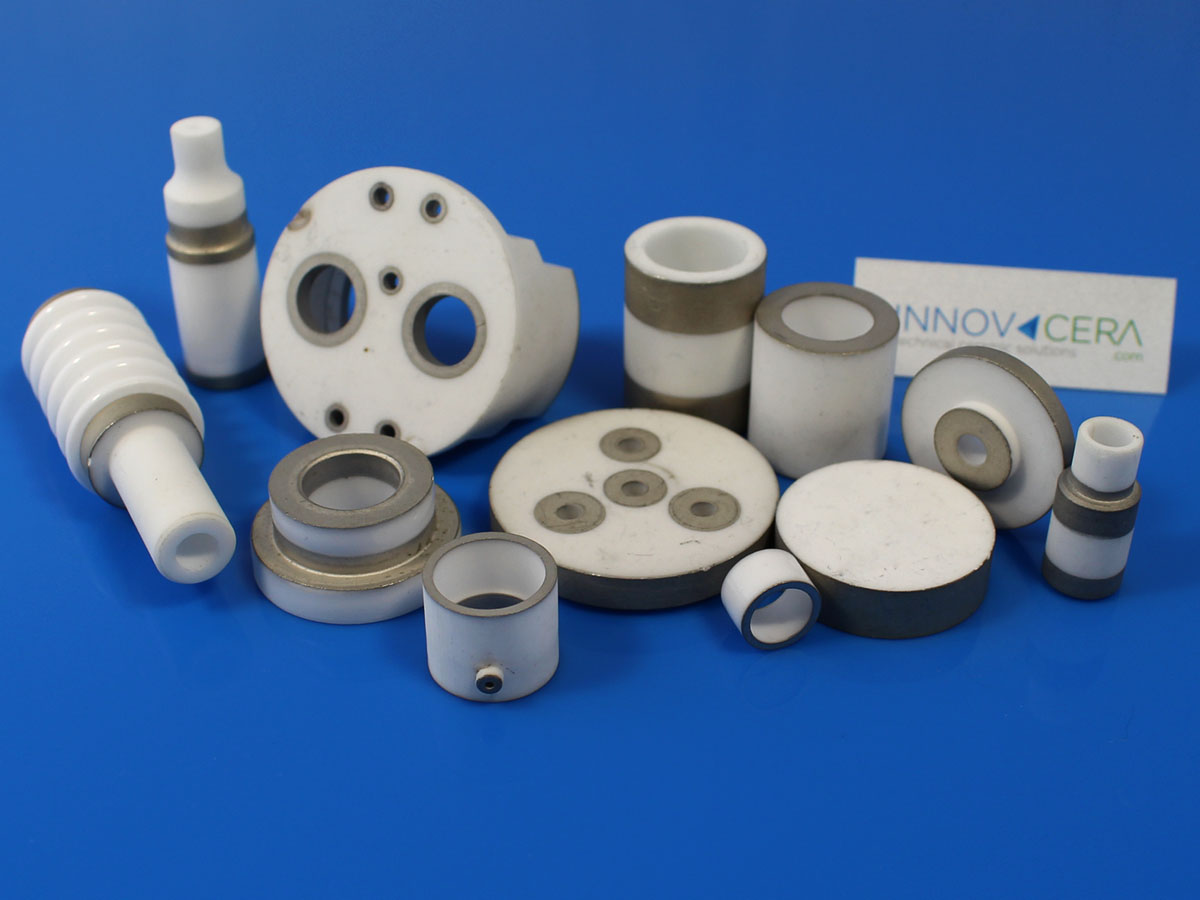

Ceramic metallization is to firmly adhere to a layer of metal film on the ceramic surface. The main role is to realize the welding between ceramic and metal. A more advanced application is to form a circuit on the surface of the ceramic, which can not only be welded but also be used as a wire to transmit current.

Nowadays, there are many methods used to manufacture metallization, including molybdenum manganese (Mo-Mn), Gold plating, Copper plating, LAP, etc.

Innovacera metallization of alumina main material is 95% alumina and 99% alumina. We will perform ceramic surface treatment before metallization to ensure the quality of metallized products.

Therefore, there will be advantages such as precision scale, small warpage, strong bonding between metal and ceramic, dense joints between metal and ceramic, and excellent heat dissipation.

So, Alumina ceramics widely used in LED heat dissipation substrates, ceramic packages, electronic circuit substrates, and electronic and electrical components.

Comments

Post a Comment