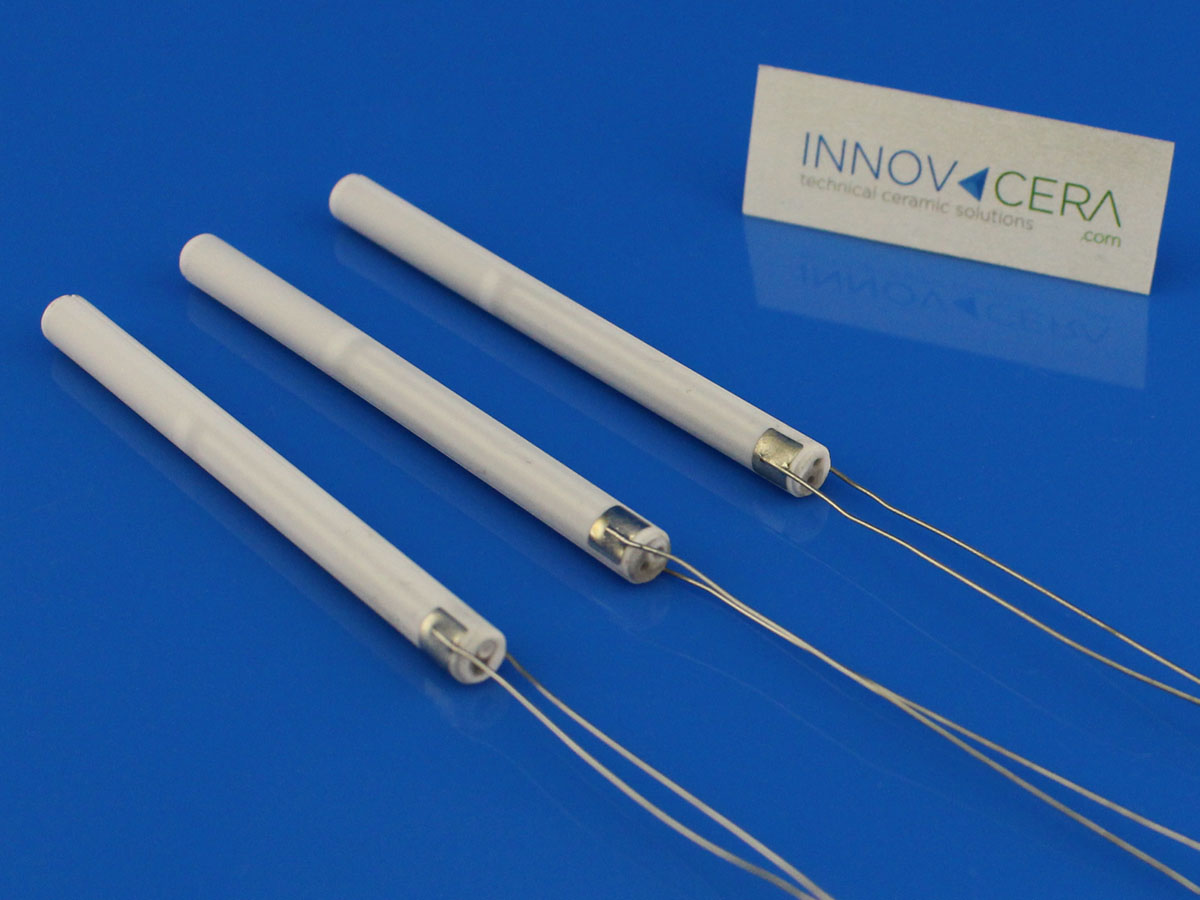

MCH Cereamic Heater Used For Soldering Iron

Source: https://www.innovacera.com/news/mch-cereamic-heater.html

A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element. Cordless irons can be heated by the combustion of gas stored in a small tank, often using a catalytic heater rather than a flame. Simple irons, less commonly used today than in the past, were simply a large copper bit on a handle, heated in a flame.

Solder melts at approximately 185 °C (365 °F). Soldering irons are designed to reach a temperature range of 200 to 480 °C (392 to 896 °F).

Soldering irons are most often used for installation, repairs, and limited production work in electronics assembly. High-volume production lines use other soldering methods. Large irons may be used for soldering joints in sheet metal objects. Less common uses include pyrography (burning designs into the wood) and plastic welding (as an alternative to ultrasonic welding).

The advantage of using an MCH ceramic heater in soldering iron are long service time, fast heating rate, energy-efficient and eco-friendly.

And the features are as below:

1. High resistivity

2. Moderate strength

3. Excellent electrical properties

4. Poor heat conductivity (Thermal insulator).

5. Good resistance to thermal shock.

6. Low coefficient of thermal expansion

7. Good mechanical stability.

Our quality inspections rules for the heater are below:

All heater should do 100% inspections before delivery. Such as Appearance Test, Straightness Test, Dimension Test, Power-On Test, Dielectric Test and Resistance Distinguish.

If you have more questions, pls feel free to contact us at email sales@innovacera.com

Comments

Post a Comment