Advantages of ceramics used in ion implanters

As an advanced semiconductor manufacturing equipment, ion implanters have very high requirements for the performance of materials.

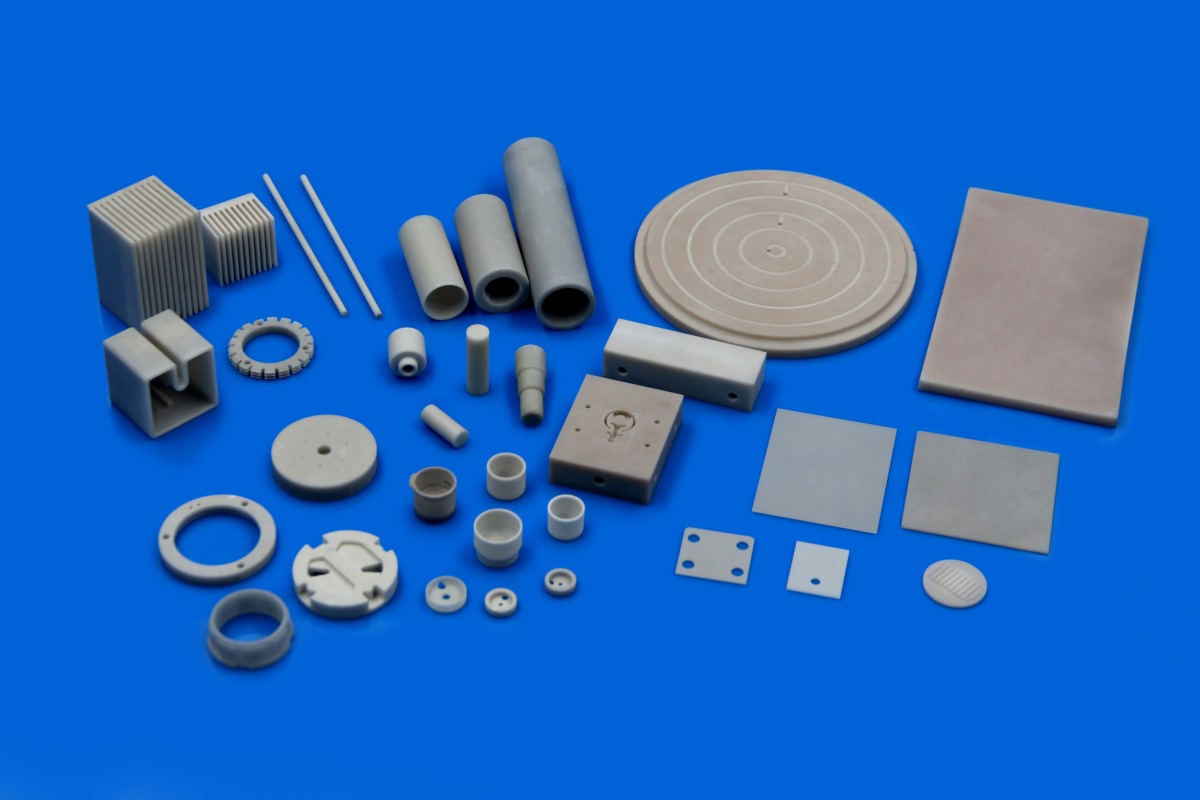

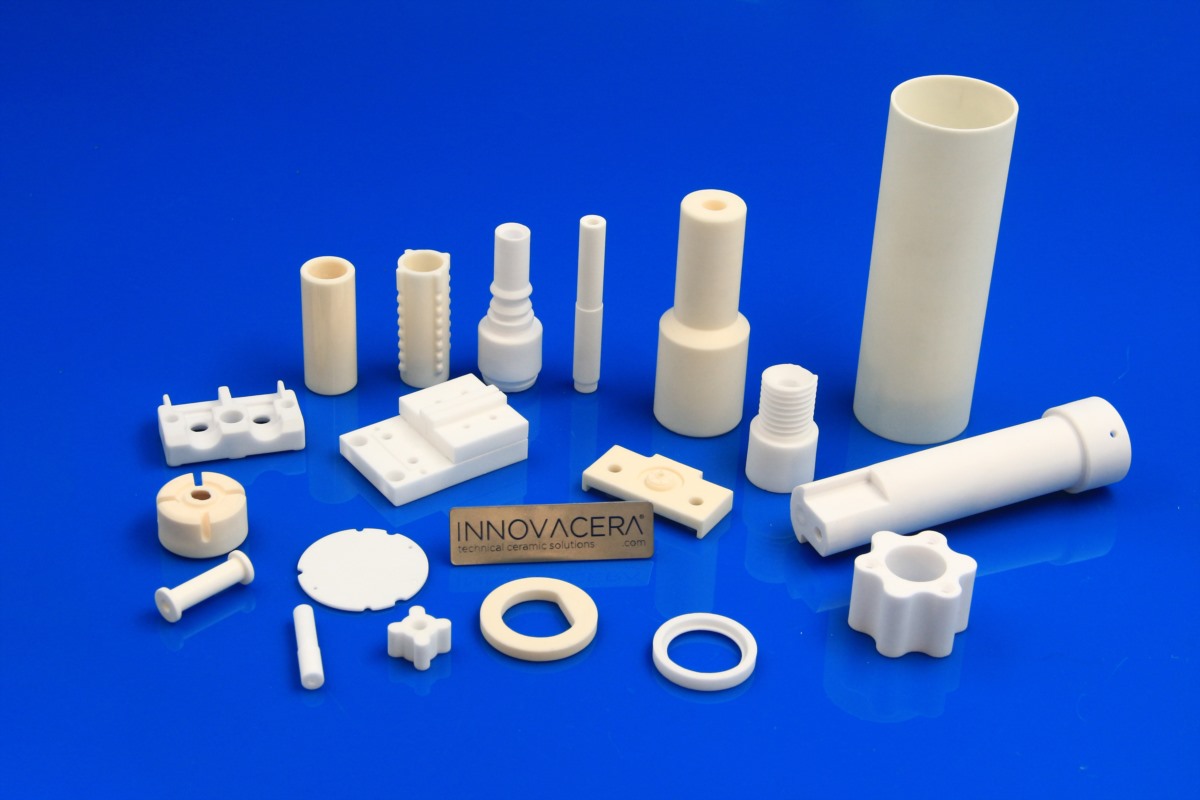

As an important component, ceramic accessories play a vital role in ion implanters.

A.Basic characteristics of ion implanter accessories and ceramic accessories

Ion implanter accessories are mainly made of high-purity silicon nitride, silicon carbide (SiC), alumina, alumina/silicon carbide microporous ceramics, aluminum nitride (AIN), sapphire and other ceramic materials, with the following characteristics:

1. High hardness and high strength: Ceramic fittings have high hardness and strength, which can withstand high load and wear during ion implantation.

2. High thermal stability: Ceramic fittings have a high melting point and can maintain stable performance in high temperature environments.

3. Good chemical stability: Ceramic accessories have good chemical stability and can work stably for a long time in harsh environments.

4. Excellent electrical insulation: Ceramic fittings have excellent electrical insulation, can withstand high voltage, and are suitable for electrical parts in ion implanters.

B. Advantages of ion implanter accessories and ceramic accessories

1. Improve ion implanter performance

The excellent performance of the ceramic accessories of the ion implanter makes the ion implanter work stably in harsh environments, improving the performance and reliability of the equipment.

2. Reduce ion implanter costs

The processing performance of ceramic accessories is good, and it can be processed by traditional metal processing methods, such as turning, milling, grinding, etc. This makes the application of ceramic accessories in ion implanters more extensive, reducing the production cost of ion implanters.

3. Promote innovation in semiconductor manufacturing materials

The successful application of ion implanter accessories and ceramic accessories provides new ideas for the research and development of semiconductor manufacturing materials, and promotes the development of semiconductor manufacturing materials in the direction of high performance and low cost

C.Application cases of ion implanter accessories and ceramic accessories

1. Ion implanter component case

Application examples of ion implanter accessories include the manufacture of key components of ion implanters, such as bearings, vacuum suction cups, electrostatic chucks, nozzles, filaments, cathode modules, etc. Due to their high hardness, high strength and high heat resistance, ceramic accessories are able to improve the performance and reliability of ion implanters.

2. Semiconductor manufacturing equipment case

Ion implanter partsExamples of semiconductor manufacturing equipment for ceramic accessories include the key components for manufacturing semiconductor manufacturing equipment, such as packaging substrates, insulating materials, etc. Due to their excellent electrical insulation and chemical stability, ceramic accessories can ensure long-term stable operation of semiconductor manufacturing equipment in harsh environments.

For more information, please contact at sales@innovacera.com.

Comments

Post a Comment