The Difference Between Electric Heating Wire And Ceramic Heater

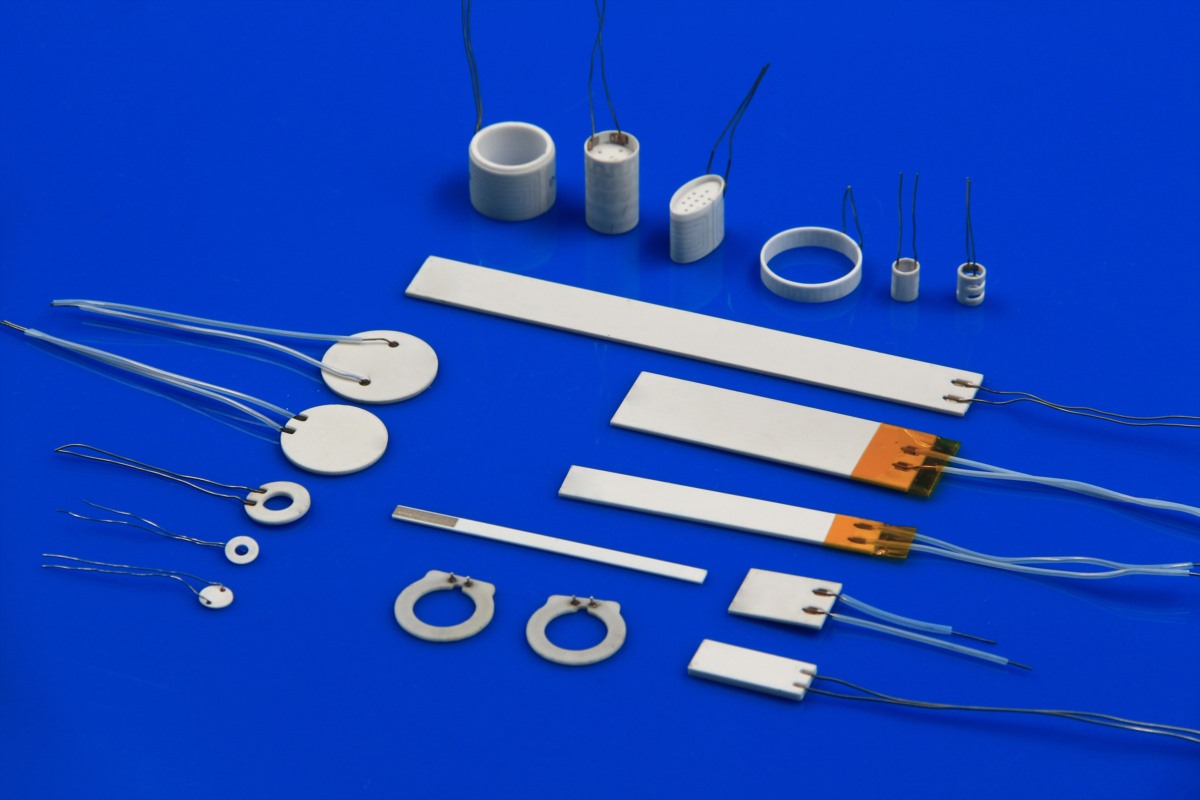

Alumina ceramic heater is a kind of high efficiency heat division uniform heater, excellent thermal conductivity of metal alloy, to ensure that the hot surface temperature uniform, eliminate the hot and cold points of the equipment. Alumina ceramic heater is divided into two kinds, respectively PTC ceramic heating body and MCH ceramic heating body. The materials used in these two products are completely different, but the finished products are similar to ceramics, so they are collectively referred to as “ceramic heating elements”.

Due to the increasingly high operating temperature requirements in modern industry, ceramic heaters can adapt to, especially chemical fiber, engineering plastics, plastic machinery, electronics, medicine, food and various pipeline heating; Ceramic heating element in which a meta tungsten or molybdenum manganese paste is printed on a ceramic casting body and laminated by hot pressing and then co-fired at 1600°C, in a hydrogen atmosphere to co-sinter ceramic and metal. Form effective high temperature, high power density, strip heater, and flexible design for easy installation.

Electric heating wire is the most common heating element, its role is to heat up after the power is turned into heat energy. The application range of electric heating wire is very wide, and a variety of common electric heating equipment will use electric heating wire as a heating element, so the electric heating wire is used in medical, chemical, electronics, electrical appliances, metallurgical machinery, ceramic glass processing and other industries.

Take the fan heater as example, the heating body with electric heating wire is more seen on the market, Its heating body is an electric heating wire, and the heat generated by the electric heating wire is blown out by a fan.

The main differences of them are as below:

1. Different materials

Ceramic heating uses PTC heating body, and electric heating wire heating is the heat generated by the heating wire inside the heating core to conduct heat to the metal tube.

2.Different insulation performance

Ceramic heating is not conductive, surface safety is not charged, good insulation performance; The electric heating wire heating is easy to leak because the metal is conductive.

3.Different properties

The biggest advantage of electric heating wire heating is that the hardness is greater than that of ceramic heating core, and it is not easy to break. The disadvantage is that the metal heating core will be oxidized at high temperature, and the efficiency of heat conduction after oxidation is much worse than that before oxidation.

The biggest feature of the ceramic heating core is that the thermal conductivity is good, and there will be no oxidation at high temperature, no matter how long it takes, the efficiency of its thermal conductivity will not have any reduction, and the disadvantage is that the robustness is relatively less than the metal heating core.

Below chart is for better understanding:

| Electric Heating Wire | Ceramic Heater |

| Fast heating speed | Long life |

| Accurate temperature control | High safety |

| Low cost | Uniform temperature |

| Short life | Lower heating speed |

| Security risks | Poor temperature control |

| Manufacturing cost is high |

According to the different demand, choose different heater material, if you need fast and accurate temperature control, use electric heating wire , if you pay more attention to safety and life ,use ceramic heater.

For more information, pls contact with us.

Comments

Post a Comment