TO 247 Alumina Ceramic Thermal Pads For Power Switches

Alumina Ceramic Thermal Pads are designed to provide a preferential heat-transfer path between heat-generating components, power switches, heat sinks, and other cooling devices. Alumina ceramic (Al₂O₃) thermal pads are renowned for their exceptional thermal conductivity and electrical insulation properties. Alumina ceramics exhibits thermal conductivity ranging from 20 to 30 W/m·K, allowing for efficient heat dissipation in high-power applications. This critical feature prevents overheating, enhancing the reliability and longevity of electronic components. Additionally, alumina’s high melting point and chemical stability make it suitable for harsh environments, ensuring these thermal pads maintain performance even under extreme conditions.

TO 247 alumina ceramic thermal pads typically used in the power switches, Integrated Circuit Chip, Packaging Heat Conduction, IGBT Transistor Heat Sink MOS Transistor, MOSFET Transistor Heat Sink Interface, LED Board TIM ( Thermal Interface Material ), COF Heat (Chip ON Film), and various electronic devices where effective heat management is crucial. Their excellent electrical insulation properties make them particularly well-suited for applications requiring high insulation resistance and low thermal resistance, such as power supply modules, inverters, and electric vehicle (EV) drive systems. As the demand for efficient thermal management solutions grows, TO 247 alumina ceramic thermal pads are increasingly integrated into designs for high-performance power electronics.

The market for TO 247 alumina ceramic thermal pads is growing with the power electronics market expands. The need for advanced thermal management solutions becomes more pronounced. With the increasing complexity and power requirements of electronic devices pushing the demand for materials that offer both high thermal conductivity and insulation. Alumina ceramic thermal pads are poised to become essential components in next-generation power electronics, ensuring efficient operation and reliability.

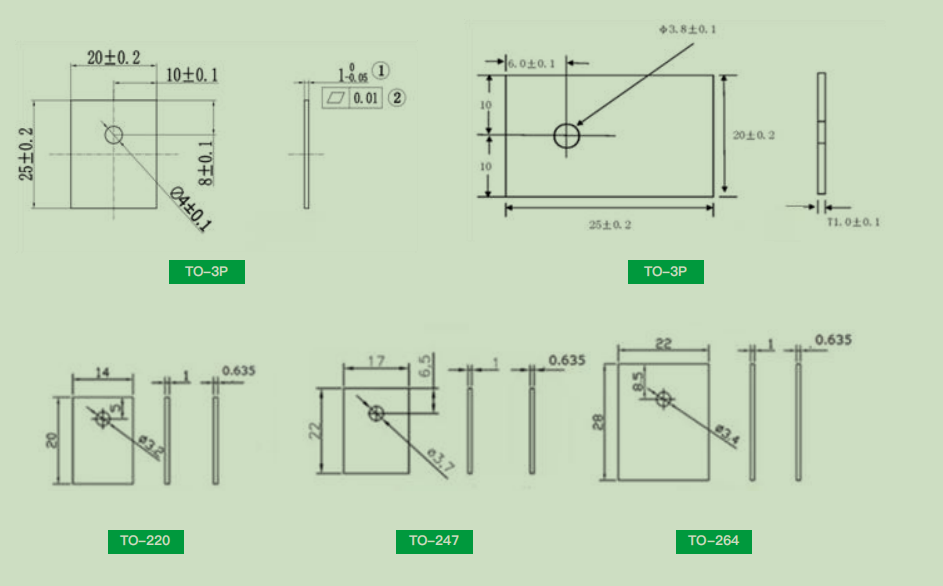

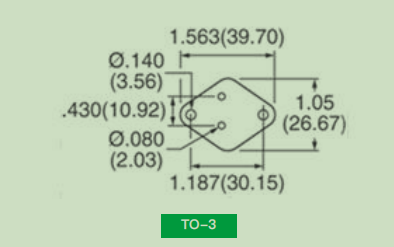

Alumina ceramic thermal pads regular model size:

TO-3P/TO-220/TO-247/TO-264/TO-3/TO-254/TO-257/TO-258,

With Hole or Without Hole.

25x20x1mm (other thickness is available, too);

20x14x1mm (other thickness is available, too);

22x17x0.635mm (other thickness is available, too);

28x22x1mm (other thickness is available, too);

39.7×26.67x1mm (Rhombus shape);

34x24x1mm (other thickness is available, too);

40x28x1mm (other thickness is available, too);

50.8×50.8x1mm (other thickness is available, too).

Other Standard Size:

114.3×114.3mm;

152x152mm;

190.5x138mm …

Customized sizes are available.

TO 247 alumina ceramic thermal pads represent a critical advancement in thermal management technologies. As industries continue to innovate, these thermal pads will play a key role in meeting the demands of future technologies.

Comments

Post a Comment