Introduction of Mass Spectrometer Filament

Principle of mass spectrometer filament

Mass spectrometer filament is also called ion source filament or cathode filament. It is mainly made of high melting point metals such as tungsten (W) or molybdenum. Its function is similar to that of ordinary filaments. It mainly produces electron emission under high pressure and excites gaseous molecules into ions, thereby generating the charge-to-mass ratio signal required for mass spectrometry.

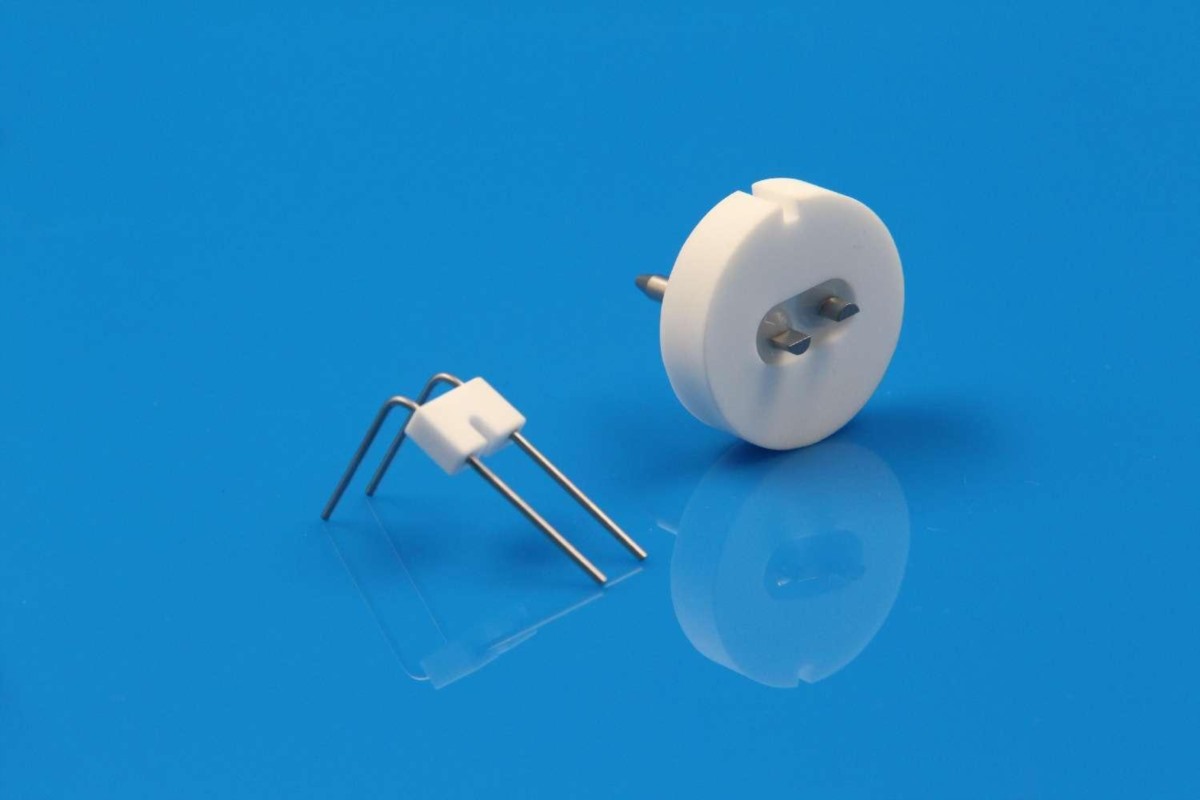

These filament supports are manufactured using 96% alumina, selected for its good electrical insulation and high-temperature stability. Customers can choose between two and four-pin options, with the pins brazed into the alumina insulator ready for filament welding. Our brazing process makes the filament considerably more resistant to higher temperatures, around 700°C compared with standard adhesives, which can only typically withstand up to 350°C.

The function of the mass spectrometer filament

In a mass spectrometer, the mass spectrometer filament is the main part of the ion source. Its role is to excite gaseous molecules into ions, and then screen and measure the charge-to-mass ratio. It is one of the core components of the mass spectrometer for mass spectrometry analysis.

The working principle of the mass spectrometer filament mainly involves the emission of electrons after being heated in a vacuum. These electrons are accelerated through the ionization chamber under the action of the electric field, and lose energy after colliding with gas molecules, which eventually leads to the ionization of gas molecules to form positive ions. This process is the basis of the work of the ion source in mass spectrometry analysis.

Type of Electron beam emitter

- TungstenFilament

- LaB6 cathode

- TFE(Thermal Field Emitter)

- Code Cathode

Below is the detail properties.

| Electron Source | Tungsten Filament | LaB6 Cathode | TFE | Cold Cathode |

| Luminance(A/cm2./sr) | -105 | -106 | -108 | -109 |

| Capacity range(eV) | 1-3 | 1-2 | 0.6 | 0.3 |

| working pressure(Pa) | <10-3 | <10-5 | <10-7 | <10-8 |

| Working temperature(K) | -2700 | -1800 | 1700-1800 | Room temp |

| Lifetime(time) | 40-100 | 200-1000 | >5000 | >10000 |

Many years of manufacturing experience with ceramic-to-metal assemblies means we can work closely with customers to tailor designs to their requirements or produce constant runs of standard designs ensuring quick turnaround and delivery.

If you need customized filament, pls contact with us.

Comments

Post a Comment