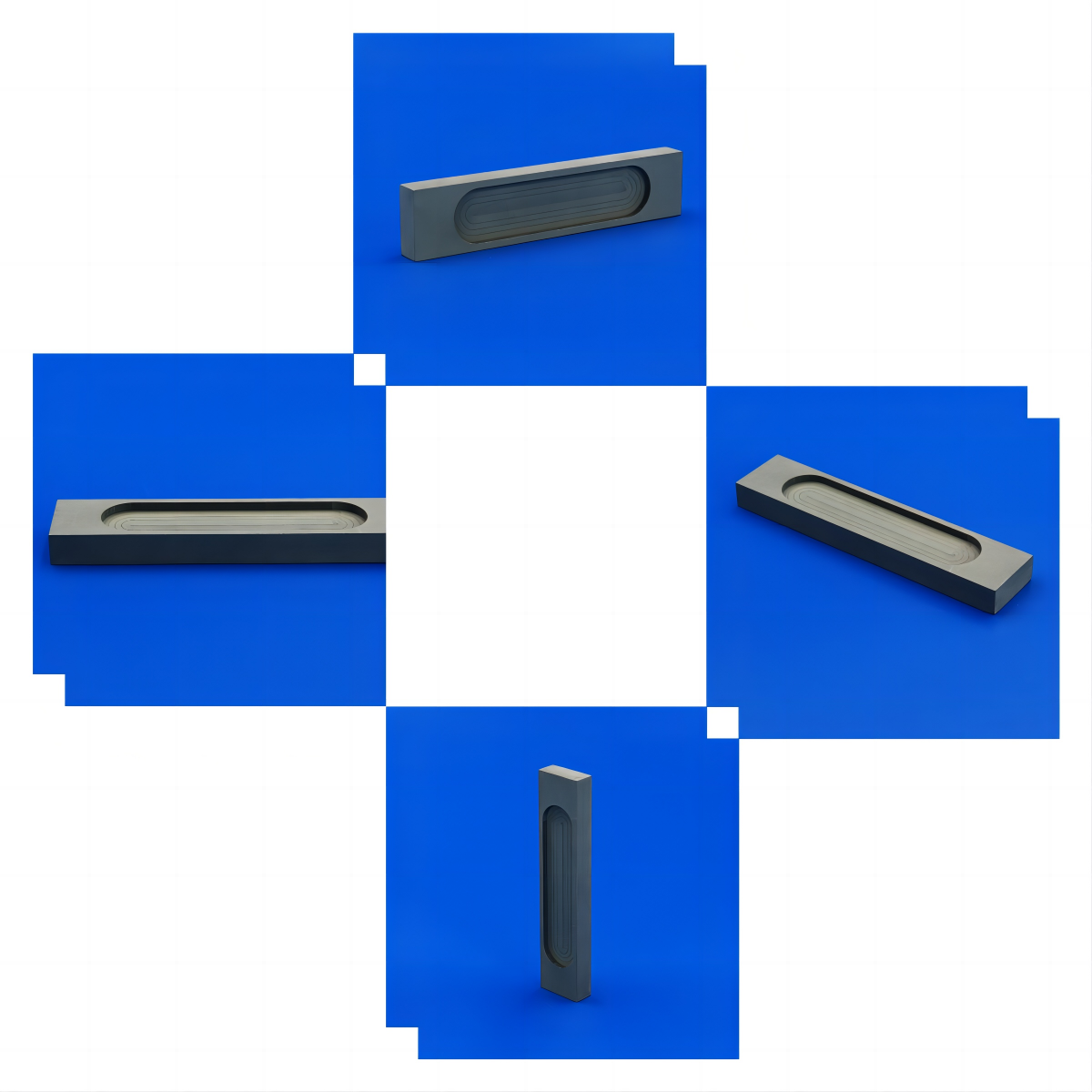

Vacuum aluminized composite conductive ceramic evaporation boat

1. Boron Nitride Evaporation Boat Application Areas:

-Areas of application:

-Packaging film aluminizing,

-Metallized film aluminizing of capacitors, Metallized coating of paper, textiles.

-metallization of hot stamping materials.

-Metallization of anti-counterfeiting signs

-Display metallization

-Solar Vacuum Aluminizing

-Semiconductor vapor deposition, germanium, nickel, titanium, electron beam -sputtering and other fields.

2. Features of Evaporation Boat:

Anti-adhesion: has good anti-adhesion, and can reduce material residue and pollution.

Conductivity: Usually has a low conductivity, which is helpful for certain processes that require controlled electron conduction.

Chemically inert: relatively inert in many chemical environments, not susceptible to corrosion

3. Evaporation Boat for Aluminum Plating:

-Shorter pre-heating time

-Better aluminum spreading capability

-Fewer sputtering and boat bending problems

-Longer service life

-More economical options

4. Innovacra’s product features and advantages:

The adoption of high purity and high quality raw materials ensures that the materials have good chemical properties.

We are adopting an international advanced vacuum hot pressing sintering method to ensure the excellent physical properties of the products.

The sintering process adopts two-way pressurization to ensure the consistency of the bulk density of the products.

Digital control of production equipment ensures stable and consistent product quality.

Unique process formula and optimized composition structure enhance the thermal shock resistance and flexural strength of the evaporation boat, improve the spreading ability and evaporation efficiency of aluminum liquid, enhance the corrosion resistance of aluminum liquid, and prolong the working life.

5. Innovacera’s Composite Ceramic Evaporation Boat Category:

- Two-component: BN+TiB2

- Three components: TiB2+ BN+ ALN

–Two-component: BN+TiB2

Main components: BN+TiB2

Density 3.0g/cm3

Bonding component: B2O3

Color: Gray

Room temperature resistivity: 300-2000 Ω-cm

Working temperature: below 1800℃

Thermal conductivity: >40W/mk

Thermal expansion coefficient: (4-6)x10-6 K

Flexural strength: >130Mpa

Evaporation rate: 0.35-0.5g/min-cm2

–Three components: TiB2 + BN + ALN

Performance reference:

Resistivity (room temperature):300-2000μΩ-cm

Evaporation rate(1450℃):0.4-0.5g/min-cm2

Working temperature ≤ 1850℃

Thermal conductivity (room temperature /1450℃):> 100/40W/mk

Thermal expansion coefficient (1450℃): (4-6)×10-6K

Flexural strength (room temperature): 150mpa

Comments

Post a Comment