How to protect mass spectrometry filament assembly?

Both ends of the LaB6 filament assembly are connected to a high-voltage power supply, creating an electric field that facilitates ionization in the vacuum. In this environment, the metal atoms within the LaB6 filament are ionized, producing positive ions and electrons. These ions are accelerated by the electric field and interact with the filament surface, causing further ionization through collisions with surface atoms. This process generates a continuous supply of ions, forming an ion cloud that, when influenced by a magnetic field, separates ions of different masses, thus enabling mass spectrum analysis.

Given that the filament is a consumable, it may degrade over time, necessitating replacement. To protect the LaB6 filament assembly and prolong its service life, it is crucial to consider several factors that can accelerate filament damage.

The influence of oxygen

A leak in the mass spectrometer can introduce oxygen into the vacuum chamber, which, when combined with the filament’s operation, can significantly speed up the degradation process. Oxygen not only affects the filament but can also prematurely age the electron multiplier. To prevent this, it is advisable to check for air leaks using an Air/Water Tune before taking samples. Common leak points include the transmission line nut or the vent valve. Applying acetone to suspected leak points can help identify leaks by observing an increase in the abundance of m/z=58 ions.

Effect of solvents

Solvents pose another significant threat to the longevity of the filament. Particularly during liquid injections, large volumes of solvent can enter the mass spectrometer, potentially burning out a filament in normal operation. To mitigate this, setting a solvent delay time can be an effective strategy to protect the filament assembly.

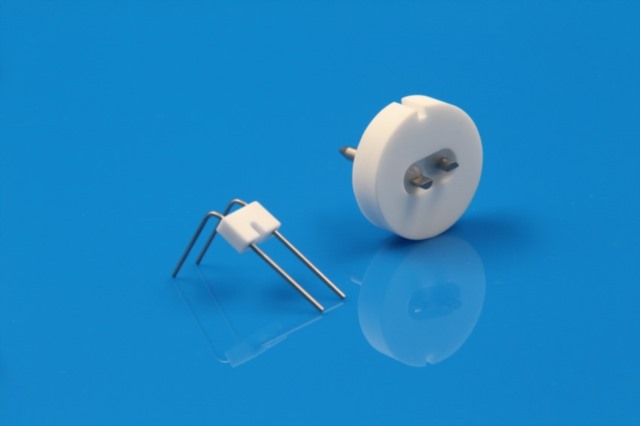

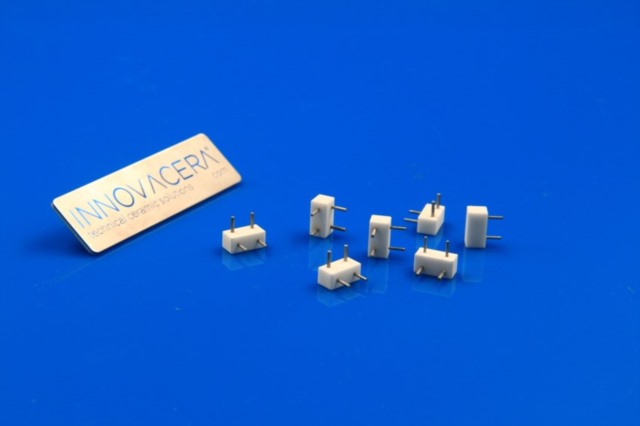

In addition to these protective measures, the choice of filament assembly material is also critical. Tungsten (W) filament assembly, for instance, is known for its robustness and resistance to wear in certain applications. However, for applications requiring high analytical performance and longevity, LaB6 filament assembly remains a superior choice.

INNOVACERA, with its extensive expertise in the production and manufacturing of filament assemblies, including LaB6 Ceramics filament assemblies, stands ready to assist with your analytical instruments components needs. Should you require a high-quality LaB6 filament assembly or have any inquiries regarding the protection and maintenance of your mass spectrometry filament assembly, please do not hesitate to get in touch with us.

Comments

Post a Comment