Applications of Boron Nitride in the metallurgical industry

1. Protective Materials

During the steel smelting process, it can be used as a protective material to protect metal materials.

For example, in the continuous casting process, Boron Nitride (BN) can be used as a protective slag to effectively prevent slag inclusion defects in castings and reduce the wear of the tundish and crystallizer.

In addition, BN can also be used as a filter material for molten metal to filter out impurities and gases in the metal and improve its quality and purity.

2. Thermal materials

Due to its high thermal conductivity and good thermal stability, this material can be used as a thermal material in the metallurgical industry.

For example, in the steel smelting process, BN can be used as the main material for high-temperature equipment such as crucibles and thermocouple sleeves and has good high-temperature oxidation resistance and high-temperature strength.

In addition, it can also be used as a lining material for high-temperature furnaces to improve the service life and safety of the furnace.

Examples: crucibles, boats, liquid metal delivery pipes, rocket nozzles, high-power device bases, molten metal pipes, pump parts, cast steel molds for melting and evaporating metals, manufacturing high-temperature components, rocket combustion chamber linings, spacecraft thermal shields, and corrosion-resistant parts for magnetofluid generators.

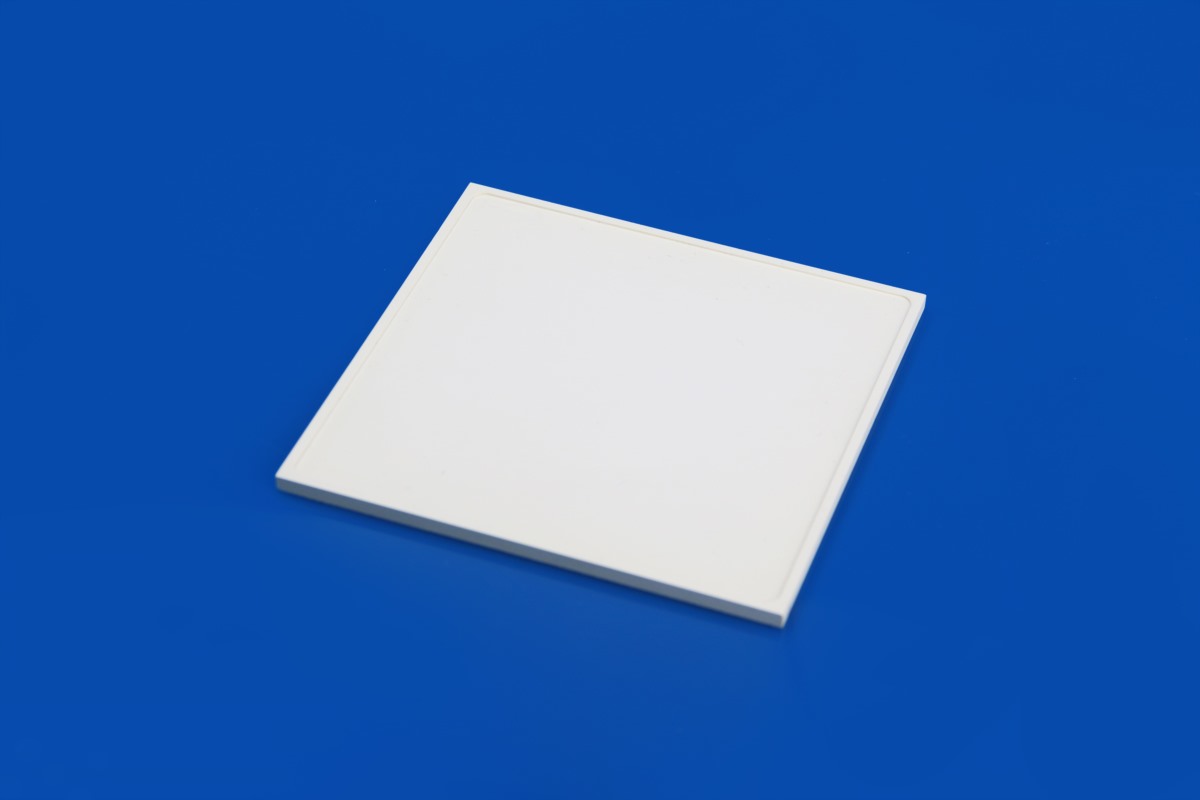

3. Heat-insulating materials

Boron nitride has excellent heat insulation properties and can be used as heat insulation material in the metallurgical industry.

For example, in the continuous casting and rolling production line of iron and steel enterprises, boron nitride can be used as heat insulation materials such as heat insulation plates and heat insulation sleeves, which can effectively reduce the heat exchange between high-temperature billets and air, and improve the production efficiency and product quality. In addition, boron nitride can also be used as heat insulation material for high-temperature furnaces to reduce heat loss and energy waste.

Examples: manufacture of high-temperature components, rocket combustion chamber lining, heat shielding of spacecraft, corrosion-resistant parts of magnetic current generators

4. Processing tools

Boron nitride has great wear resistance and lubricity and can be used as a machining tools in the metallurgical industry.

For example, in metal cutting processing, BN can be used as a tool coating material to improve the tool's wear resistance and service life.

In addition, BN can also be used as abrasives, abrasives, and other processing aids to improve processing efficiency and surface finish.

Comments

Post a Comment