Features and Benefits of Boron Nitride Ceramic Evaporation Boat Sets

In the vast landscape of advanced materials, Boron Nitride Ceramics (BNCs) are a remarkable class of compounds renowned for their exceptional thermal stability, chemical inertness, and lightweight properties. Among the myriad applications that leverage these unique characteristics, Boron Nitride Ceramic Evaporation Boat Sets have emerged as indispensable tools in high-temperature processing industries, particularly in semiconductor manufacturing, vacuum metallization, and advanced coating technologies.

The Essence of Boron Nitride Ceramics

Boron Nitride (BN), a compound of boron and nitrogen, exists in various crystalline forms, each with distinct properties. Among them, hexagonal boron nitride (h-BN) and cubic boron nitride (c-BN) are the most commonly utilized in ceramic applications. BNCs, particularly those made from pyrolytic processes, exhibit unparalleled resistance to extreme temperatures, making them ideal candidates for use in environments where conventional materials would fail.

Pyrolytic Boron Nitride Ceramics: The Elite of the BNC Family

Pyrolytic Boron Nitride (PBN) Ceramics are produced through a highly specialized process involving decomposing a boron-containing precursor gas under high temperature and controlled conditions. This results in a dense, highly pure ceramic with exceptional thermal shock resistance and low thermal expansion coefficients. PBNCs’ ability to withstand temperatures exceeding 2000°C without significant degradation or softening makes them the material of choice for BNC Evaporation Boat Sets.

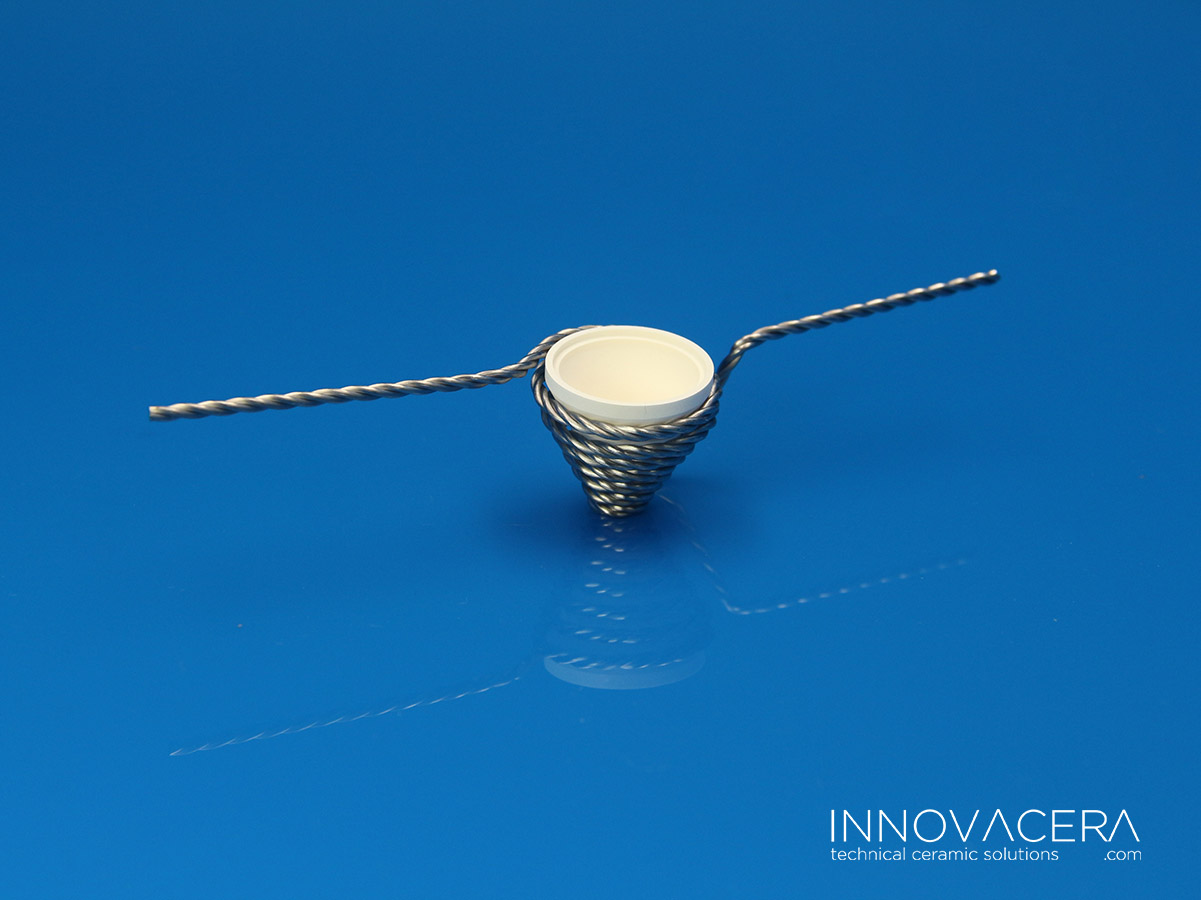

The Role of Boron Nitride Ceramic Evaporation Boat Sets

BNC Evaporation Boat Sets are precision-engineered devices designed to efficiently and uniformly deposit thin films of metals, alloys, or other materials onto substrates in vacuum chambers. These boats are typically made from PBNCs due to their superior thermal conductivity and resistance to contamination from the evaporating material. The evaporation process relies on heating the material inside the boat to a high temperature, causing it to vaporize and condense onto the target surface, forming a uniform and high-quality coating.

Advantages of BNC Evaporation Boat Sets

High-Temperature Stability: PBNC’s ability to withstand extreme temperatures ensures uninterrupted operation, even during prolonged or intensive evaporation cycles.

Chemical Inertness: The non-reactive nature of BNCs protects the boat from corrosion or contamination by the evaporating materials, ensuring the purity of the final product.

Low Thermal Expansion: PBNCs’ low coefficient of thermal expansion minimizes dimensional changes during heating and cooling cycles, preserving accuracy and precision.

Longevity: The durability of PBNCs extends the lifespan of the evaporation boat, reducing maintenance costs and downtime.

Versatility: Suitable for a wide range of materials, including metals, alloys, and even some refractory compounds, making BNC Evaporation Boat Sets ideal for diverse applications.

Boron Nitride Ceramic Evaporation Boat Sets, crafted from the pinnacle of Pyrolytic Boron Nitride (PBN) Ceramics, represent a pinnacle of innovation in high-temperature processing technologies. Their unparalleled thermal stability, chemical inertness, and longevity make them invaluable assets for industries seeking precision, efficiency, and reliability in their manufacturing processes. As the demand for advanced materials and coatings continues to grow, the role of BNC Evaporation Boat Sets will only become more prominent, driving further advancements in the field of advanced ceramics and beyond.

Comments

Post a Comment