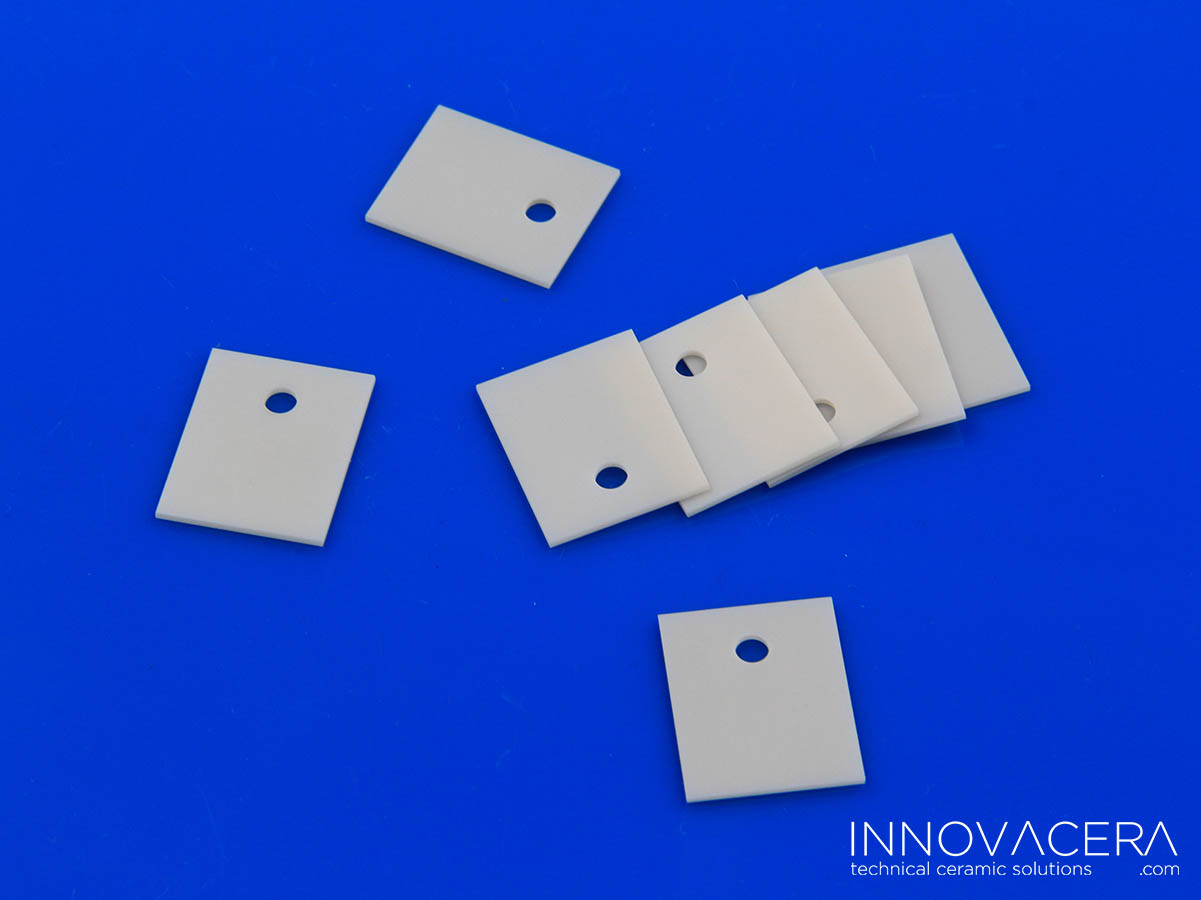

Aluminum Nitride Ceramic Thermal Pads

Innovacera Ceramic Thermally Conductive Interface Pads are designed to provide a preferential heat-transfer path between heat-generating components, heat sinks, and other cooling devices.

The pads are used to fill air gaps caused by imperfectly flat or smooth surfaces which should be in thermal contact.

The pads are made by ceramic material such as alumina ceramic and aluminum nitride, which help in providing enhanced thermal conductivity and excellent insulation performance.

Aluminum Nitride Ceramic Thermal Pads Regular Size:

For Package Type: TO-3P/TO-220/TO-247/TO-264/TO-3/TO-254/TO-257/TO-258, With Hole or Without Hole.

- TO-3P 25x20x1mm (other thickness is available, too);

- TO-220 20x14x1mm (other thickness is available, too);

- TO-247 22x17x0.635mm (other thickness is available, too);

- TO-264 28x22x1mm (other thickness is available, too);

- TO-3 39.7×26.67x1mm (Rhombus shape);

- TO-254 34x24x1mm (other thickness is available, too);

- TO-257 40x28x1mm (other thickness is available, too);

- TO-258 50.8×50.8x1mm (other thickness is available, too).

Other Standard Size:

- 25.4×25.4mm;

- 114.3×114.3mm;

- 152x152mm;

- 190.5x138mm …

Customized sizes are available.

Ceramic Thermal Pads Installation Steps:

- Clean the target surface: Clean the dust or stains on the surface of the object to be installed, and then align the hole position of the ceramic insulating sheet;

- Power tube bonding: Stick the power tube on the ceramic insulating sheet;

- Fixed the insulation sheet: Use screws to fix the power tube and ceramic insulating sheet on the installation object.

ALN Product Package Requirement:

- The product is cleaned according to the requirements, after completely dried, placed in the special pearl cotton packaging box.

- One group of 100 pieces of products is placed in the small cells in the packaging box. There are 5 cells in each packaging box, and 500 pieces can be placed in total.

- After each version of the packaging box is filled with products, it needs to wrap the film tightly, and attach the quantity label.

- Put the pearl-cotton packing box into the outer carton, paste the specification and quantity label on the surface.

- Package carton size: 21x21x12cm

- Gross weight: 1.5kgs

Applications:

- Power Devices

- MOS Transistor

- Heat Sink Interface

- MOSFET Transistor

- IGBT Transistor Heat Sink

- Chip ON Film (COF) Heat Conduction

- LED Board Thermal Interface Material (TIM)

- Integrated Circuit (IC) Chip Packaging Heat Conduction

Comments

Post a Comment