Application of Ceramic Materials In Thermal Management Of New Energy Vehicle Batteries

With the rapid development of new energy vehicles, batteries, as one of their important components, have become increasingly prominent in terms of thermal management. Battery temperature control in high or low temperature environments is a key factor in ensuring battery performance and safety.

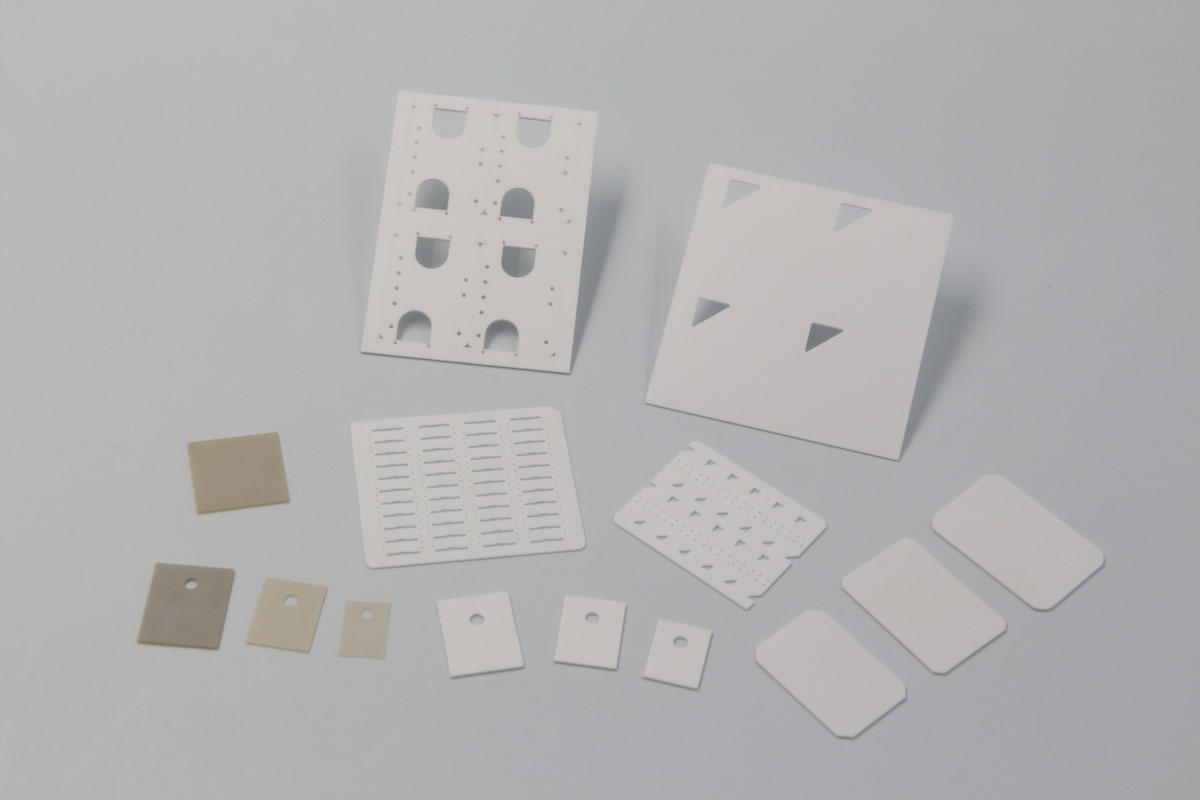

1. Advantages of ceramic materials in battery thermal management

Ceramic materials have outstanding advantages in battery thermal management, which are mainly reflected in the following aspects. First, ceramic materials have excellent thermal conductivity. Since batteries generate a lot of heat during operation, the high thermal conductivity of ceramic materials can quickly transfer heat to the external environment, effectively reducing the battery temperature. This helps to improve the working efficiency and life of the battery and reduce safety hazards caused by overheating. Secondly, ceramic materials show good high temperature resistance. Under high temperature environment, ceramic materials can maintain high thermal and chemical stability, and are not prone to structural damage and performance degradation. This makes ceramic materials a reliable choice for battery thermal management, which can maintain the integrity and performance stability of the material under harsh working conditions. In addition, ceramic materials also show excellent corrosion resistance. Battery systems are often in harsh environments such as humidity and corrosive gases. Ceramic materials can work stably for a long time under these conditions, reducing the maintenance cost and energy consumption of the battery system. Its corrosion resistance helps protect battery components and extend the service life of the entire system.

2. Application scenarios of ceramic materials in battery thermal management

Ceramic materials have many application scenarios in battery thermal management. Their excellent thermal conductivity and high temperature resistance can achieve efficient thermal management. The following are several important application scenarios of ceramic materials in battery thermal management.

2.1 Thermal insulation layer of battery shell material

In new energy vehicle battery systems, the selection of battery shell materials is crucial to temperature control. Ceramic materials have lower thermal conductivity and can effectively prevent heat conduction compared to metal materials. When the battery shell is made of ceramic material, the thermal impact of the external temperature on the inside of the battery can be reduced. This helps to maintain the stability of the internal temperature of the battery and avoid battery performance fluctuations caused by changes in external temperature. In addition, ceramic materials have excellent insulation properties that can prevent the conduction of heat and current. This insulation property can avoid problems such as the diffusion of heat or leakage inside the battery caused by changes in external temperature. By using ceramic materials as battery shell materials, the internal temperature of the battery can be ensured to be stable and the safety and reliability of the battery system can be protected.

2.2 Thermally conductive materials inside the battery

By placing ceramic materials inside the battery module, the heat generated inside the battery can be effectively conducted and quickly transferred to the heat dissipation system, thereby achieving efficient thermal management. The high thermal conductivity of ceramic materials can greatly reduce the rate of temperature rise of the battery, avoiding performance degradation and safety risks caused by overheating. This application solution helps to improve the working efficiency and stability of the battery system of new energy vehicles.

2.3 Battery heat dissipation packaging

Using ceramic materials as heat dissipation packaging materials can optimize their thermal conductivity. Ceramic materials have a high thermal conductivity coefficient, can quickly conduct heat, and effectively reduce thermal resistance. By optimizing thermal conductivity, the efficiency of heat conduction from battery components to the heat dissipation system can be improved, thereby reducing the operating temperature of the entire battery system. In addition, the heat conduction path can also be optimized. By designing a reasonable heat conduction path, the heat conduction efficiency can be maximized and heat loss can be reduced. Ceramic materials have good deformation stability and mechanical strength, which can maintain the stability and reliability of the heat conduction path and ensure that heat can be effectively conducted to the heat dissipation system.

2.4 Battery heat plate design

As a key component to balance the temperature difference between battery components, the battery heat plate plays an important role in battery thermal management. The application of ceramic materials can effectively improve the performance and effect of battery heat plates. Ceramic materials have excellent thermal conductivity and high temperature resistance, and can quickly and evenly conduct heat to achieve temperature balance between battery components. Its high thermal conductivity allows heat to be quickly transferred from high temperature areas to low temperature areas, reducing temperature gradients and avoiding local temperatures that are too high or too low.

Ceramic materials play an important role in battery shell insulation, thermal conductive materials, heat dissipation packaging and battery heat plate design due to their excellent thermal conductivity, high temperature resistance and corrosion resistance.

For more questions, pls contact with us.

Comments

Post a Comment