Multiple Connectors Explained: A Reliable Solution for Advanced Electronics

In the realm of advanced electronics, the demand for reliable, high-performance connectors has never been greater. Among the numerous options available, Multiple Connectors stand out for their versatility and robustness. These connectors play a critical role in ensuring stable and efficient connections in various high-tech industries, particularly in applications where Ceramic-to-Metal integration is crucial.

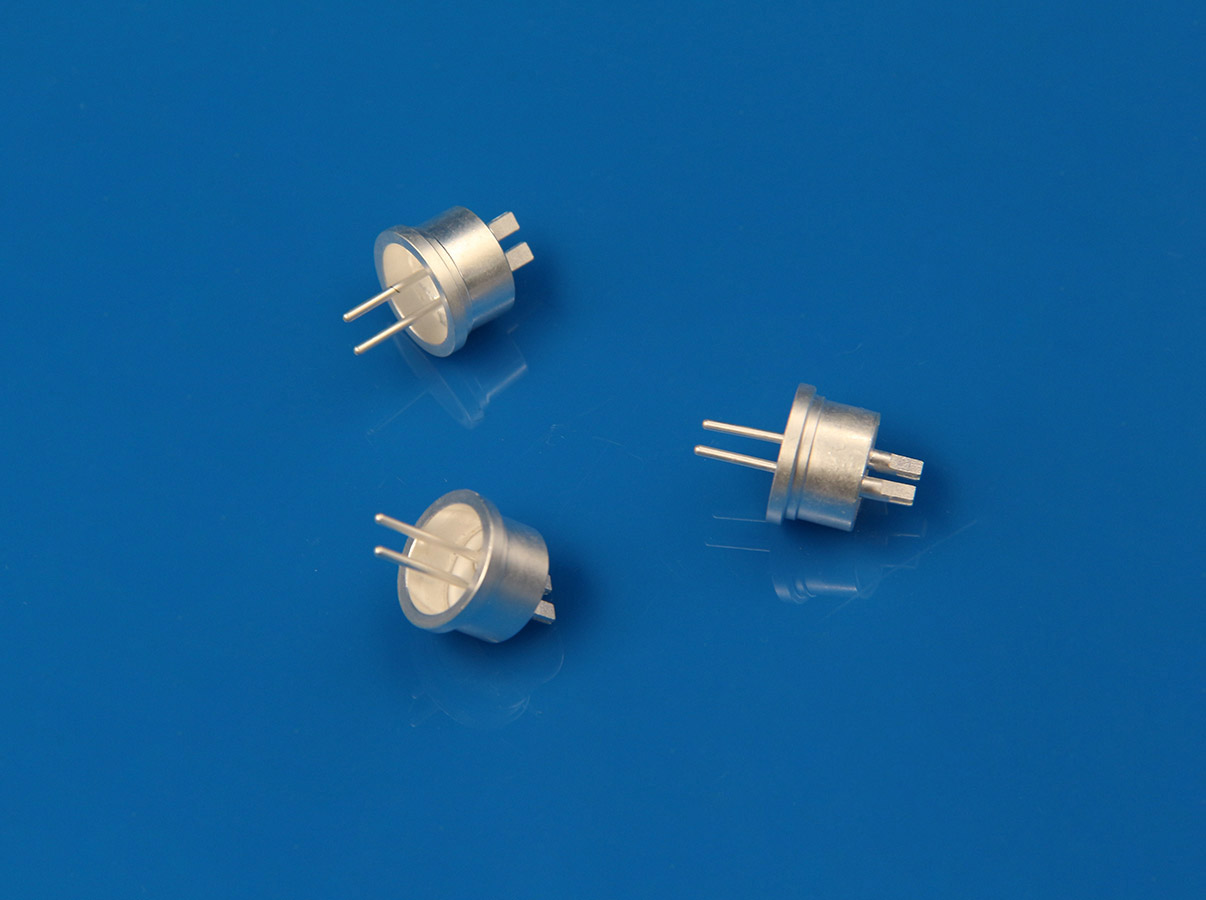

Understanding Multiple Connectors

Multiple Connectors are designed to accommodate several electrical connections within a single housing, making them ideal for complex systems where space and reliability are paramount. These connectors are often used in environments where harsh conditions, such as high temperatures and corrosive atmospheres, are present. Their ability to maintain a stable electrical connection, even under extreme conditions, makes them indispensable in industries like aerospace, defense, and medical devices.

The Role of Ceramic-to-Metal Seals

A key feature of Multiple Connectors is the incorporation of Ceramic-to-Metal seals. These seals provide a hermetic barrier, ensuring that the connectors remain unaffected by environmental factors such as moisture, dust, and temperature fluctuations. The ceramic component, typically made from Alumina Ceramic (Al₂O₃), is known for its excellent electrical insulation properties and high thermal stability. This makes it an ideal material for use in environments where both electrical insulation and mechanical strength are required.

Alumina Ceramic (Al₂O₃): Enhancing Connector Performance

Alumina Ceramic (Al₂O₃) plays a crucial role in the performance of Multiple Connectors. Its high dielectric strength and low dielectric loss make it an excellent choice for applications requiring superior electrical insulation. Additionally, Alumina’s resistance to wear and corrosion ensures that the connectors can withstand the rigors of demanding environments, extending their operational life. The use of Alumina in Ceramic-to-Metal sealing also enhances the mechanical strength of the connectors, making them more resistant to mechanical stress and vibration.

Applications of Multiple Connectors

Thanks to their robust design and reliable performance, Multiple Connectors are employed in a wide array of applications. In the aerospace industry, they are often used in avionics systems, satellite communications, and other critical systems where reliability is non-negotiable. In the medical field, these connectors are used in diagnostic equipment and implantable devices, where their small size and high reliability are essential. Additionally, the defense industry relies on Multiple Connectors for secure communication systems, radar equipment, and other mission-critical applications.

Multiple Connectors represent a vital component in modern electronic systems, providing reliable and efficient connections in a variety of challenging environments. By leveraging the benefits of Ceramic-to-Metal sealing and Alumina Ceramic (Al₂O₃), these connectors offer exceptional performance and durability. As technology continues to advance, the importance of high-quality connectors like Multiple Connectors will only grow, making them an integral part of the future of electronics.

Comments

Post a Comment