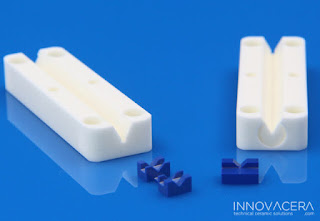

Zirconia Ceramic V Groove Parts For Optical Fiber Fusion Splicer

The Zirconia Ceramic V-Groove is an important part of the optical fiber fusion splicer. Its function is to fix and support the left and right optical fibers in the fusion splicing process. It is used in ribbon optical fiber fusion splicer for fusing ribbon optical fiber, leather wire fusion splicer for fusing covered cables and jumpers, and polarization maintaining optical fiber fusion splicing machine for fusing polarization maintaining optical fiber, etc.

Zirconia ceramic is commonly used in optical fiber fusion splicers for several reasons:

Low thermal expansion: Zirconia ceramic has a low coefficient of thermal expansion, which means it doesn’t expand significantly when exposed to high temperatures. This property ensures that the splicer maintains a stable structure during the fusion process.

Chemical resistance: Zirconia ceramic is highly resistant to chemicals, including acids and alkalis. This resistance ensures that the ceramic components remain intact and unaffected by the chemicals used in fiber splicing.

High temperature resistance: Zirconia ceramic can withstand high temperatures, making it suitable for use in the heating elements of fusion splicers.

Excellent electrical insulation: Zirconia ceramic is an electrically insulating material, preventing any unwanted electrical currents from interfering with the fusion process.

High mechanical strength: Zirconia ceramic has a high strength-to-weight ratio, making it the perfect material for components that need to withstand mechanical stress during fiber splicing.

Zirconia ceramic provides the necessary mechanical strength, thermal stability, electrical insulation, and chemical resistance required for the efficient and reliable fusion splicing of optical fibers.

Comments

Post a Comment