Ceramic to Metal Sealing

Ceramic to Metal Sealing

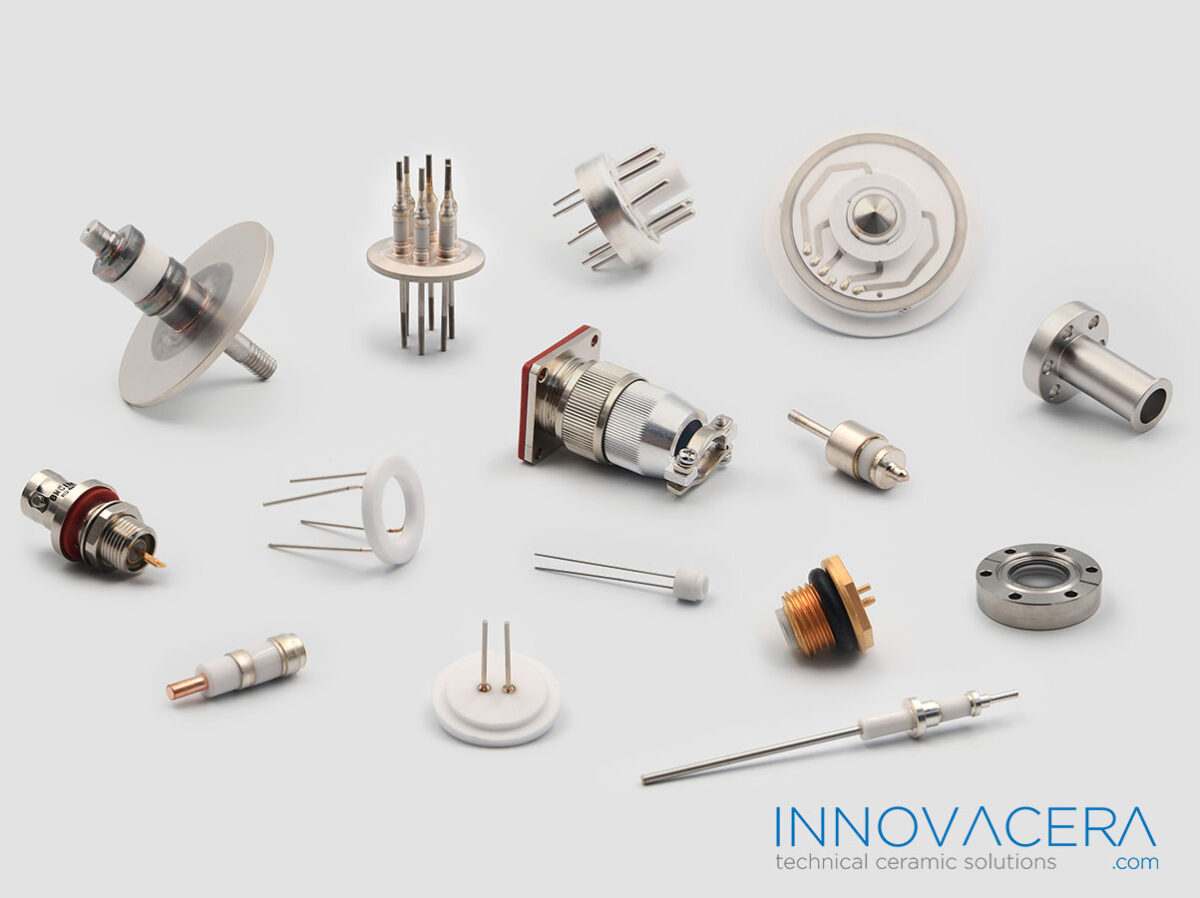

INNOVACERA offer customers a wide variety of vacuum-tight, hermetically sealed ceramic-to-metal, glass-ceramic and glass-to-metal components. Ceramic-to-metal sealing products not only have the characteristics of ceramic high temperature resistance, corrosion resistance, but also have the strength and toughness of metal. They are widely used in electronic aerospace, medical industry and other applications.

The best customer service and effcient solution could be provided is INNOVACERA commitment.

The best customer service and effcient solution could be provided is INNOVACERA commitment.

Ceramic-to-Metal Sealing Materials:

| Housing Material | Insulator | Conductor |

| NiFe Alloys & NiFeCO (Kovar) | 94%-99% Al2O3 | Kovar ; Copper Cored Kovar |

| 300 & 400 Series SST | AlN | 52 Alloy |

| Cu and Cu Alloys | BeO | Inconel |

| Inconel | Stainless Steels | |

| 42, 46, 49 Alloys |

Hermetic Seal Properties:

- Hermeticity: up to 1×10-9 atm cc/sec He

- Working Temperature > 500°C depending on materials and geometry

- Insulation Resistance: Typically exceeds 1 GΩ @ 100 VDC

Ceramic-to-Metal Sealing Features:

- High Abrasion Resistance

- High Mechanical Strength

- Pressures over 10,000 PSI

- High Temperature Usage

- Low Dielectric Loss

- Mass Spectrometer Leak Tested

- High Chemical Stability

Ceramic-to-Metal Welding Process:

- Cleaning

- Pasting

- Metallizing

- Nickel Plating

- Mounting

- Welding

- Inspection&Packing

Ceramic-to-Metal Sealing Applications:

- Relay Insulators

- Capacitor

- Magnetrons

- Travelling Wave Tube

- X-ray Tube Components

- Electrosurgical Instrumentation

- Implantable Packages and Feedthroughs

- Gas Detectors

- Microscopes (TEM, SEM)

- High Voltage Feedthroughs

- High-temperature Feedthroughs

- RF Feedthroughs

- Optoelectronics and Power Tube

- Laser Tubes

- Thyristors

- Diodes

- And etc

Comments

Post a Comment