Ceramic Components Improve Photovoltaic Efficiency

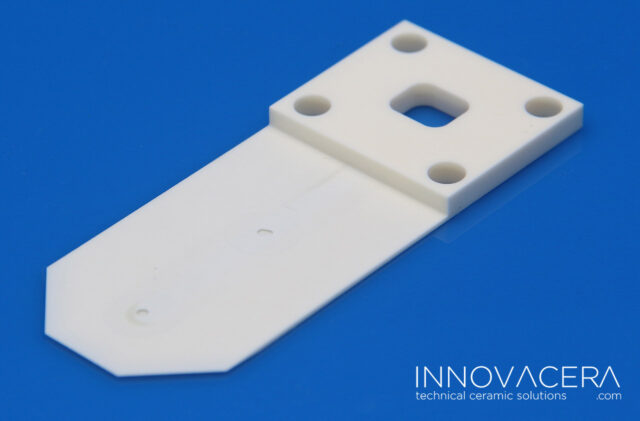

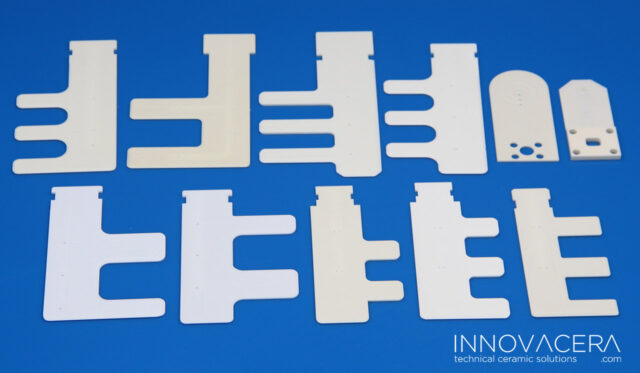

Below is some typical ceramic products for Photovoltaic industry.

Innovacera produced precision ceramic components which have a positive effect on durability in the photovoltaic industry. Advance ceramic components play a important role in solar energy technology and improve efficiency in various areas of photovoltaic systems.Ceramic insulation rings for thermal decoupling in solar systems.

Ceramic encapsulation offer superior thermal conductivity, facilitating efficient heat dissipation from the solar cells, thereby mitigating thermal stress and enhancing overall performance. Also provide a robust barrier, safeguarding the delicate solar cells throughout their operational lifespan.

Ceramic heat sinks protect from overheating in high-concentration photovoltaic systems .

Fine ceramic bearings and bushings are used in the drives of tracked photovoltaic systems.

Ceramic rollers give precise rolling of flat wires in PV systems.

High thermal ceramic substrates for solar application.

Ceramic components are widely use in the photovoltaic industry is because of their excellent properties in corrosion resistance, good electrical insulator and mechanical strength. So the alumina ceramic, zirconia ceramic, silicon nitride ceramic, aluminum nitride is ideal ceramic material for making ceramic part for photovoltaic industry.

Alumina ceramic material properties is as below:

| Properties | Units | Alumina Ceramic | |||

| Purity | wt% | 95% | 99% | 99.80% | |

| Volume Density | g/cm3 | 3.65 | 3.8 | ≥3.89 | |

| Water Absorption | % | 0 | 0 | 0 | |

| Crystal Size(Grain Size) | μm | 4-5 | 4-5 | 4-5 | |

| Vickers Hardness, HV1.0 | Gpa | 14 | 1600 | ≥15 | |

| Flexural Strength | Mpa | 300 | 310 | ≥300 | |

| Coefficient of Linear | 20-500℃ | 1×10-6 | 6.5-7.5 | 6.5-7.5 | 6.5~7.5 |

| Expansion | 20-800℃ | mm/℃ | 6.5-8.0 | 6.5-8.0 | 6.5~8.0 |

| Thermal Conductivity | W/m·K( 20℃) | 20 | 25 | ≥20.9 | |

| Specific Heat Capacity | KJ/(kg·K) | ≥0.8 | ≥0.8 | ≥0.8 | |

| Dielectric Strength | KV/mm | ≥12 | 15*106 | ≥12 | |

| Volume Resistivity | Ω·cm 20℃ | ≥1014 | ≥1014 | ≥1014 | |

| Ω·cm 300℃ | ≥1011 | ≥1011 | ≥1011 | ||

| Ω·cm 500℃ | ≥109 | ≥109 | ≥109 | ||

| Dielectric Constant | 1MHz | 9 | 9-10 | 9-10 | |

| Tangent of Dielectric Loss | 1MHz | ≤4×10-4 | ≤2×10-4 | ≤3×10-4 | |

| Surface Roughness | μm | 0.4 After Machine | 0.1-0.4 After Machine | 0.1-0.4 After Machine | |

| Max Working Temperature | ℃ | 1600 | 1600 | 1650 | |

Photovoltaic system needs ceramic suction plate, ceramic rack, ceramic top tooth block, top comb pins, side comb plates as below are very hard to machine because it needs high quality control in the flatness, deformation and surface finish and Innovacera make it.

As insulator materials, ceramics are key components of energy saving solutions. Within the energy sector, ceramic components are also used in machinery for energy production, including bearings, plate, rods, valves, seals, spheres, pumps, sheaths, and tubes for wind turbines, gas turbines, oil and gas extraction equipment, and other systems.

In addition to their electrical and thermal properties, ceramic parts contribute to the optical enhancement of solar panels. Ceramics play a crucial role in the manufacturing of solar commentators, which focus sunlight onto photovoltaic cells to intensify energy generation. Ceramics, with their ability to withstand high temperatures and harsh operating conditions, serve as ideal materials for the fabrication of concentrator components, ensuring long-term performance and reliability.

Comments

Post a Comment