Aluminum nitride (AlN) Substrates

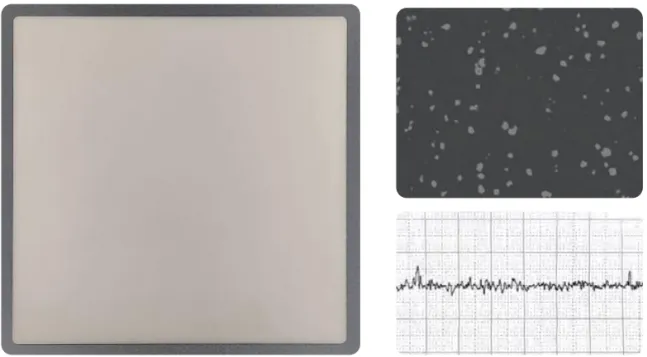

Innovacera’s Aluminum Nitride (AlN) Substrates deliver exceptional thermal conductivity, a thermal expansion coefficient closely matched to silicon, and excellent electrical insulation, making them an ideal choice for high-power electronic applications. With superior mechanical strength, high breakdown voltage, and outstanding thermal shock resistance, AlN substrates ensure reliable performance in demanding environments. Their precision machining capability and customizable specifications make them well-suited for IGBT power modules, high-power LEDs, and advanced heat dissipation components.

Features

• High thermal conductivity

• Thermal expansion coefficient close to silicon wafer

• High breakdown voltage

Application

• High power IGBT power module

• High-power LED

• High power heat sink

Material Properties Table

| Project | Test conditions | Unit | AlN | |||

| AN-170 | AN-200 | AN-230 | ||||

| Material | – | – | AlN | AlN | AlN | |

| Appearance | – | – | Light blue | beige | beige | |

| Surface roughness | Ra | μm | 0.2~0.75 | 0.2~0.75 | 0.2~0.75 | |

| Density | – | g/cm 3 | ≥3.3 | |||

| Physical properties | Bending strength | 3 -point bending resistance | MPa | ≥400 | ≥350 | ≥300 |

| Vickers hardness | Load 4.9 | GPa | ≥10 | |||

| Water absorption | – | % | – | |||

| Thermal performance | Thermal conductivity | 25℃ | W/(m·k) | ≥170 | ≥200 | ≥230 |

| Linear thermal expansion coefficient | 25-500℃ | x10 -6 mm/℃ | 4~6 | |||

| Thermal shock resistance | 800℃ | Time | ≥10 | |||

| Specific heat | – | J/(kg·K) | 720 | |||

| Electrical properties | Dielectric constant | 1MHz/25℃ | – | 8~9 | ||

| Dielectric loss | 1MHz/25℃ | x10 -4 | ≤3 | |||

| Volume resistivity | 25℃ | Ω·cm | > 10 14 | |||

| Breakdown voltage | – | kV/mm | > 17 | |||

| Light performance | Reflectivity | Reflectivity meter | – | – | ||

| Whiteness | Whiteness meter | – | – | |||

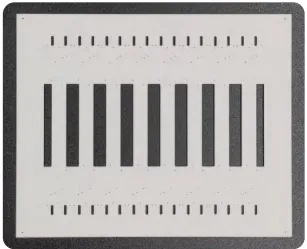

Specifications and Dimensions

| Size(mm) Thickness ( mm ) | 0.25 | 0.38 | 0.5 | 0.635 | 0.76 | 1.0 | 1.2 | 1.5 | 2.0 |

| 101.6*101.6 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 114.3*114.3 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 120*120 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 138*190 | √ | √ | √ | √ | √ | √ | √ |

Processing

• Laser processing

• Grinding and polishing sheet roughness table

| Project | Qualified | Special Grade | ||

| Internal dimension tolerance | ±0.05mm | ±0.03mm | ||

| External dimension tolerance | ±0.15mm | ±0.1mm | ||

| Hole tolerance (φ0.07-0.15mm) | ±0.05mm | ±0.02mm | ||

| Hole tolerance (φ > 0.15mm) | ±0.1mm | ±0.02mm | ||

| Project | Surface roughness (μm ) | |||

| Qualified | Special Grade | |||

| Grinding | 0.3-0.6 | 0.3-0.5 | ||

| Fine grinding | 0.1-0.4 | 0.1-0.3 | ||

| Polishing | ≤0.1 | ≤0.05 | ||

.jpg)

Comments

Post a Comment