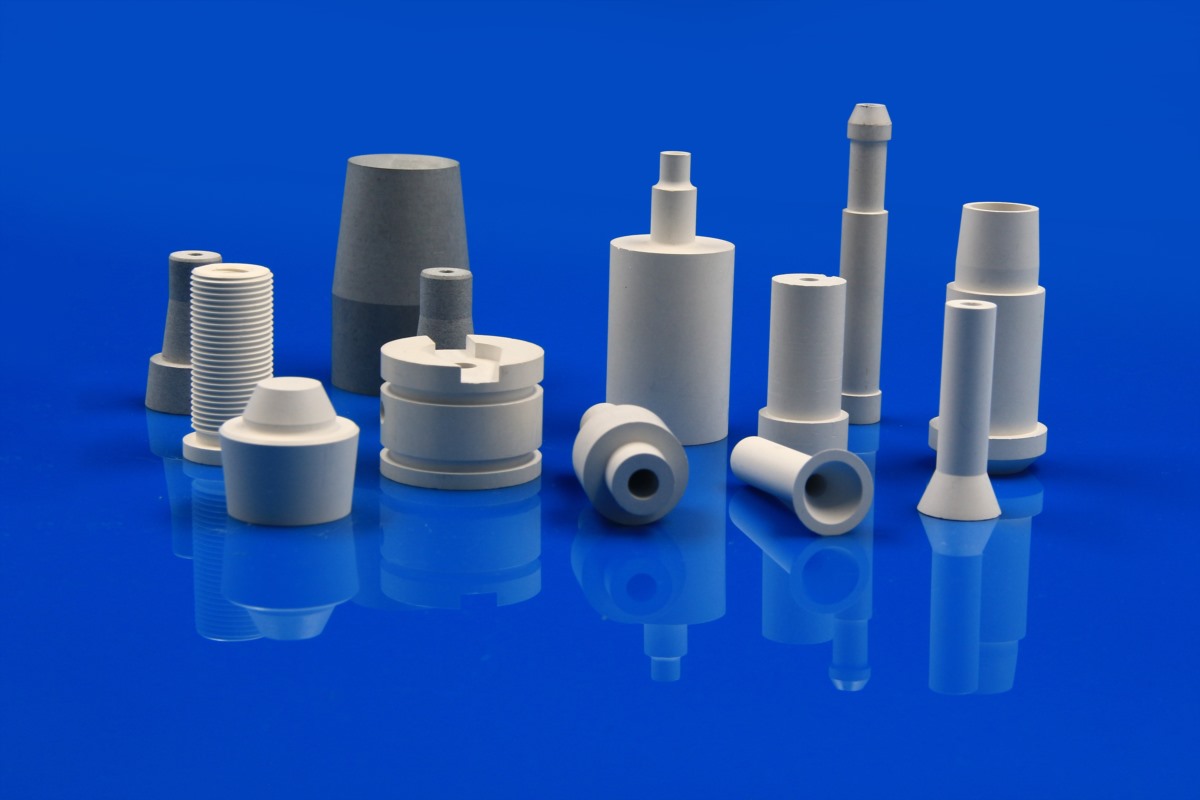

The use of boron nitride ceramic and zirconia ceramic nozzles in different processes of powder metallurgy

In powder metallurgy (PM) processes, boron nitride and zirconia ceramic nozzles are used depending on the type of metal materials.

Main Features of Ceramic Nozzles

High-temperature resistance: withstands temperatures above 1500 °C from molten metals or plasma flames.

Wear resistance: resists erosion from powder or gas flow for long-term operation.

Chemical inertness: does not react with active metals or gases.

Applications at Different Stages of Powder Metallurgy

| Stage | Process | Functions of Nozzles | Ceramic Nozzles | Typical Metals |

|---|---|---|---|---|

| Powder Preparation | Gas Atomization | High-pressure inert gas (such as nitrogen or argon) impinges on the molten metal stream to form fine powder; ceramic nozzles control flow and particle size. | Boron Nitride and Zirconia | High-purity or reactive metals such as titanium and nickel-based alloys. |

| Water Atomization | Ceramic nozzles provide corrosion resistance and precise flow control. | Zirconia | Used in high-pressure water atomization for preparing low-cost powders such as iron-based powders. | |

| Powder Spraying or Deposition | Thermal Spraying | During coating or preform preparation (e.g., plasma spraying or HVOF), ceramic nozzles spray metal powders onto substrates to form dense coatings. | Boron Nitride and Zirconia | Applicable to all metal powders. |

| Powder Transportation and Treatment | Fluidized Bed or Pneumatic Transportation | Ceramic nozzles are used to control gas flow, evenly disperse or convey powders, and prevent agglomeration or clogging. | Boron Nitride and Zirconia | Tungsten, molybdenum, iron, cobalt, nickel, aluminum, titanium, tantalum, and other active metal powders. |

| Treatment After Sintering | Cooling or Atmosphere Control | Ceramic nozzles spray inert gases (e.g., hydrogen, nitrogen) or cooling media to control furnace atmospheres and accelerate part cooling to prevent oxidation. | Boron Nitride and Zirconia | High-performance metal powders such as high-speed steel, titanium alloys, and amorphous/metallic glass powders. |

| 3D Printing (e.g., Binder Jetting) | – | Ceramic nozzles are used to accurately spray binders or metal slurries. | Boron Nitride and Zirconia | Powder metallurgy additive manufacturing applications. |

| Degreasing or Cleaning | – | Ceramic nozzles are used to remove temporary binders or residual powder from compacts. | Zirconia | Titanium and its alloys, nickel-based superalloys, aluminum alloys, cobalt-chromium alloys, refractory metals (tungsten, tantalum, molybdenum), precious metals (gold, silver, platinum), and high-entropy alloys. |

Table 1: Boron Nitride Ceramic Nozzle Properties

| Properties | Units | BMA | BSC | BMZ | BSN |

|---|---|---|---|---|---|

| Main Composition | – | BN + Zr + Al | BN + SiC | BN + ZrO₂ | BN + Si₃N₄ |

| Color | – | White Graphite | Greyish-Green | White Graphite | Dark Gray |

| Density | g/cm³ | 2.25–2.35 | 2.4–2.5 | 2.8–2.9 | 2.2–2.3 |

| Three-Point Bending Strength | MPa | 65 | 80 | 90 | 150 |

| Compressive Strength | MPa | 145 | 175 | 220 | 380 |

| Thermal Conductivity | W/m·K | 35 | 45 | 30 | 40 |

| Thermal Expansion Coefficient (20–1000 °C) | 10⁻⁶/K | 2.0 | 2.8 | 3.5 | 2.8 |

| Max Using Temperature (Atmosphere / Inactive Gas / High Vacuum) | °C | 900 / 1750 / 1750 | 900 / 1800 / 1800 | 900 / 1800 / 1800 | 900 / 1800 / 1800 |

| Room Temperature Electric Resistivity | Ω·cm | >10¹³ | >10¹² | >10¹² | >10¹³ |

| Typical Applications | – | Powder metallurgy, metal casting, high-temperature furnace components, crucibles, casting molds for precious and special alloys, high-temperature supports, and nozzles or transport tubes for molten metals. | |||

Table 2: Zirconia Ceramic Nozzle Indicators

| Indicators | Item | Units | MSZ-H | MSZ-L | Custom |

|---|---|---|---|---|---|

| Main Composition | ZrO₂ | % | ≥95 | ≥95 | 60–95 |

| Al₂O₃ | % | ≤0.2 | ≤0.2 | 0.2–20 | |

| SiO₂ | % | ≤0.4 | ≤0.4 | 0.2–1 | |

| MgO | % | ≤2.9 | ≤2.9 | MgO / Y₂O₃ | |

| Fe₂O₃ | % | ≤0.1 | ≤0.1 | 0.1–0.3 | |

| TiO₂ | % | ≤0.1 | ≤0.1 | 0.1–1.0 | |

| Physical Properties | Color | – | Yellow | Yellow | Yellow / White |

| Density | g/cm³ | ≤5.2 | 5.4–5.6 | 4.6–5.6 | |

| Porosity | % | ≤18.5 | ≤8 | 1–18.5 | |

| The stabilizers, grain composition, and porosity can be customized according to specific operating environments. | |||||

Comments

Post a Comment