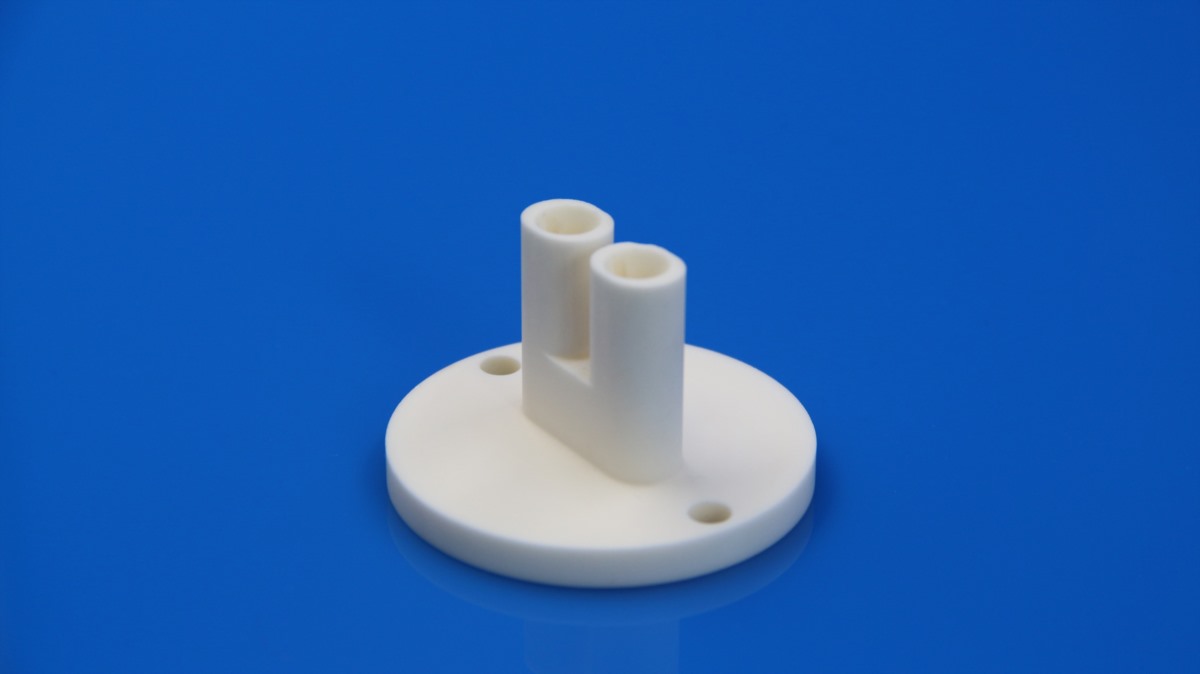

Ceramic Parts For Electron Generator Components

Innovacera recently are researching and developing to produce alumina ceramic (Al₂O₃) parts for Electron Generator Components.

Electron generator components are essential devices or parts used to generate, control, and direct electron flows. These components are crucial in semiconductor manufacturing and various high-tech applications.

Ceramic parts play a crucial role in electron generator components due to their excellent electrical insulation, thermal stability, and resistance to high temperatures and corrosion. Here are some key ceramic parts used in electron generator components.

- CeramicInsulators

- Ceramic filaments

- Ceramic feedthroughs

- Vacuum Chambers

- Electron Emission Sources

- Support Structures

- Ceramic heat shields

- Ceramic capacitors

- DielectricsCeramics

- Electrodes

Here are the key aspects of electron generator components:

1. Electron Gun

- Function: Generates and emits an electron beam, commonly used in electron microscopes, electron beam lithography equipment, and electron beam welding.

- Components: Cathode (heated to emit electrons), grid (controls the intensity of the electron beam), and anode (accelerates the electrons).

2. Power Supply

- Function: Provides a stable current and voltage to drive the electron gun and maintain its normal operation.

- Characteristics: High stability, low noise, precise control.

3. Focusing System

- Function: Uses electromagnetic or electrostatic lenses to focus the electron beam, achieving the required precision and resolution on the target area.

- Components: Electromagnetic lenses, electrostatic lenses.

4. Deflection System

- Function: Controls the direction of the electron beam to precisely position it on the target surface.

- Components: Deflection coils or deflection electrodes.

5. Vacuum System

- Function: Provides and maintains the high vacuum environment necessary for the electron generator to operate, reducing collisions between electrons and gas molecules.

- Components: Vacuum pumps, vacuum chamber.

6. Cathode Materials

- Function: Serve as the source material for electron emission, typically requiring high electron emission efficiency and high-temperature resistance.

- Common Materials: Tungsten (W), WF6, LAB6.

7. Insulation and Shielding Components

- Function: Prevents electron beam leakage and protects equipment and operators from radiation damage.

- Materials: Ceramics, glass, metal shielding.

8. Cooling System

- Function: Dissipates heat, ensuring that the various parts of the electron generator operate within a safe temperature range.

- Components: Liquid cooling systems, air cooling systems.

Applications

- Semiconductor Manufacturing: Electron beam lithography, etching, and inspection.

- Materials Science: Electron microscopes (SEM, TEM) for material structure analysis.

- Medical Equipment: Radiation therapy devices.

- Industrial Processing: Electron beam welding, cutting.

Electron generator components precisely control the generation, focus, and deflection of electron beams, these components support a wide range of complex manufacturing and analysis processes.

Comments

Post a Comment