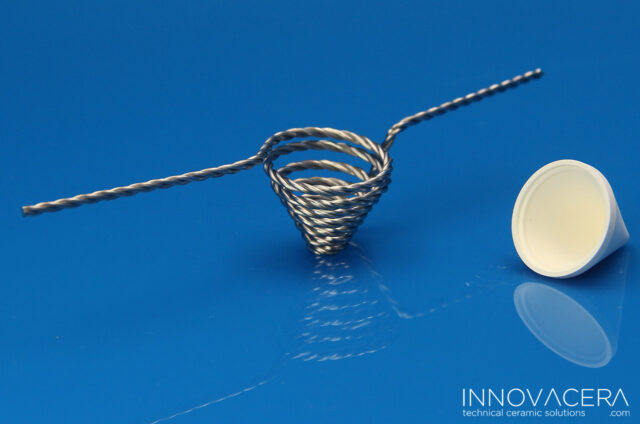

Boron Nitride Ceramic Evaporation Boat Sets For Thermal Evaporation

Innovacera offers an extensive selection of boron nitride ceramic evaporation boat sets, readily available for purchase. The remarkable sales volume of this series has surpassed 10,000 units, attesting to its popularity and reliability. The BN ceramic evaporation boat, functioning equivalently to internally heated ceramic containers, caters to a wide spectrum of metal evaporation processes, encompassing precious metals like gold and silver, as well as various other metals and alloys including copper, zinc, nickel, and chromium.

Notably, this boron nitride evaporation boat ensures the complete evaporation of most metals without any loss, with the added advantage of re-usability for the evaporation tungsten basket. Our innovatively developed ceramic evaporation boats offer a novel solution for thermal evaporation needs, serving as invaluable assets for scientific research and metal production requirements alike. Available in sizes ranging from 0.25ml to 3ml, these boats provide versatility to suit diverse application needs.

Innovacera specializes in the development and production of boron nitride products, primarily manufacturing ceramic insulating components, crucibles, tubes, rings, sheets, shaped parts, boats, nozzles, and other boron nitride ceramic products. These products have found successful implementation in ultra-high-tech applications across various fields, including ultra-high temperature equipment production, powder metallurgy gas atomization processing, thermal plastic molding, optical glass manufacturing, horizontal continuous casting, amorphous strip production, technical ceramic components sintering, fluorescent powder sintering, metal casting, electronics industry, superhard materials development, semiconductor fabrication, and aerospace technology applications.

The distinctive features of boron nitride ceramic evaporation boats contribute significantly to their effectiveness in thermal evaporation processes:

- High Purity: Boron nitride ceramic ensures the purity of the evaporated material, minimizing contamination and enhancing the quality of the deposited thin films.

- Low gas content: BN boats is the minimal presence of gases within the material of the evaporation boats, which can otherwise interfere with the evaporation process or lead to contamination of the deposited thin films

- High density: High-density materials are more robust and can withstand the mechanical stresses and thermal cycling inherent in thermal evaporation operations

- Uniform grain: A uniform grain structure ensures homogeneous properties throughout the material, including thermal conductivity, mechanical strength, and chemical stability.

- Good compactness: the tight packing of grains within the boron nitride ceramic material, resulting in a dense and homogeneous structure.

- Complete Evaporation: The design of boron nitride ceramic evaporation boats facilitates the thorough evaporation of most metals without any loss, ensuring maximum efficiency in material utilization.

Comments

Post a Comment