Magnesium Stabilized Zirconia Ceramic

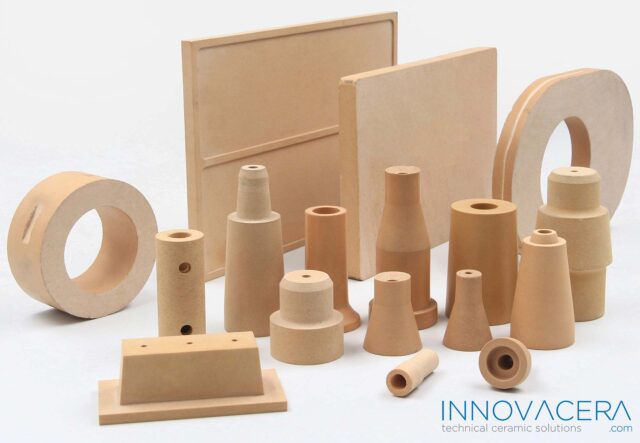

Magnesium Stabilized Zirconia Ceramic – For Ultra-High Temperature

Introduction

Magnesia Stabilized Zirconia (MSZ) is a great refractory and insulating material due to high oxygen ion conductivity, high strength and toughness, and good thermal shock resistance. It has a clean melt at temperatures above 1900°C and above and is specially manufactured for melting superalloys and precious metals. Its superior thermal shock resistance to temperatures reaching up to 2200°C.

Prime Features:

- High thermal shock resistance

- High wear-resistant and erosion-resistant

- Metal corrosion resistance in high temperature

- Excellent non-wetting characteristics

- High strength

- Long service life

- The stabilizers and grains combination can be designed according to customer’s using environment.

Application temperature: 0°C-2200℃

Applicable environment: Air, Vacuum, or Atmosphere Protection Environment

Application Field:

High temperature melt flow control

-Sizing nozzle, Ladle skateboard panel, Converter slag blocking slide plate and ring, etc

Specialty glass manufacturing

-Large size high content of zirconia and alumina ceramics, etc

Metal powder industry

-Setter plate, Gas atomizing nozzle, etc

Precious metal smelting industry

-Ceramic Crucibles, etc

Artificial/Laser Crystal Ceramic Temperature Field

-Rare earth composite oxide solid solution ceramic temperature field, etc

Technical Indicators:

| Indicators | Item | Units | MSZ-H | MSZ-L | Custom |

| Main Composition | ZrO2 | % | ≥95 | ≥95 | 60-95 |

| Al2O3 | % | ≤0.2 | ≤0.2 | 0.2-20 | |

| SiO2 | % | ≤0.4 | ≤0.4 | 0.2-1 | |

| MgO | % | ≤2.9 | ≤2.9 | MgO/Y2O3 | |

| Fe2O3 | % | ≤0.1 | ≤0.1 | 0.1-0.3 | |

| TiO2 | % | ≤0.1 | ≤0.1 | 0.1-1.0 | |

| Physical | Color | – | Yellow | Yellow | Yellow/White |

| Density | g/cm3 | ≤5.2 | 5.4-5.60 | 4.6-5.6 | |

| Porosity | % | ≤18.5 | ≤8 | 1-18.5 | |

| The stabilizers, grains combination and porosity can be designed according to customer’s using environment. | |||||

Comments

Post a Comment