What are the applications of ceramic heat sinks for thermal management?

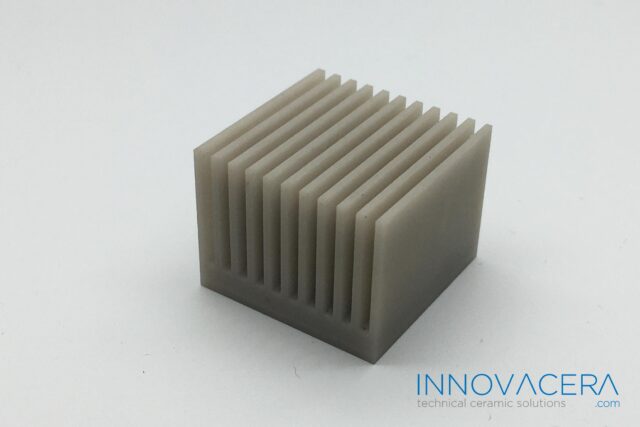

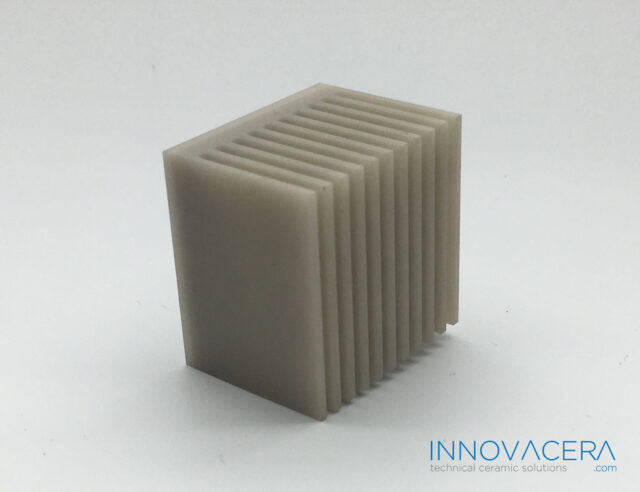

Highly thermally conductive ceramic heat sinks made of aluminum oxide and aluminum nitride offer many possibilities in thermal management of high-performance electronics, photovoltaics, LEDs and other applications. These products offer high electrical insulation, chemical resistance, corrosion resistance and numerous benefitsapplication.

Cooling in Automotive Engineering

Hybrid and electric vehicles (HEV hybrid vehicles, BEV pure electric vehicles) especially require drive motors with the highest possible power output, long service life and extremely high reliability in the smallest space.

This is where efficient liquid coolers offer decisive advantages: due to their very low thermal resistance, both thermally and electrically, since the ceramic heat sink itself is already an excellent insulator.

1. Thermal management of inverters and converters for hybrid and electric vehicles

2. Insulating ceramics for high-voltage PTC heating modules in hybrid and electric vehicles

3. Electrical insulation and cooling for lighting applications (laser lamps, LEDs)

4. Cooling of start-stop system

5. Battery Thermal Management: Uses the same ceramic components for heating during startup and cooling during operation

6. Cooling solutions for electric vehicles

Cooling of power electronic equipment

In the field of power electronics, heat sink chip technology can reduce the thermal resistance between the heat source (chip) and the heat sink by half compared to traditional cooling system structures, depending on the structure.

1. Electronic power modules with extremely high packaging density

2. Frequency converters in wind turbines

Cooling in energy production

High concentration photovoltaics (CPV/HCPV) is a futuristic technology that harvests energy from light: sunlight beams are tightly bundled together and concentrated on a small surface using high-power solar cells. If not cooled effectively, they will be destroyed in a short time.

In order to operate a CPV system at maximum efficiency, effective cooling is required, even during operation.

Cooling in LED lighting technology

LEDs have many advantages over traditional light bulbs. A key benefit is significantly longer lifespan. However, this depends heavily on the temperature the LED chip reaches during operation. A general rule of thumb is: if the operating temperature is reduced by 10°C, the life of the product will be doubled. This is why cooling LED chips is so important.

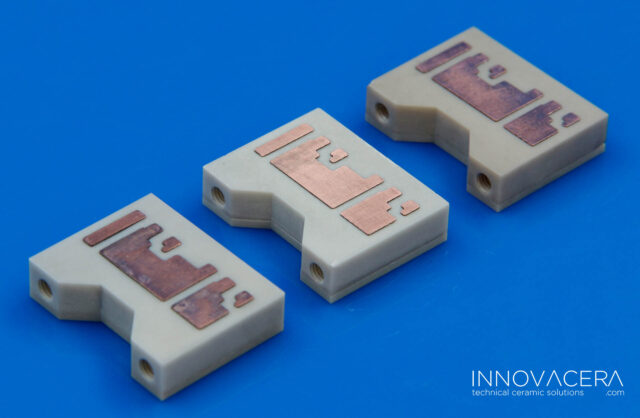

In addition, circular heat sinks with direct metallized circuits on ceramics can be used in LED technology, such as for shop and store lighting, to achieve the brightest lighting with the lowest power consumption.

1. Store and shop lighting

2. UV hardening

3. Parking and street lighting

4. Facade lighting

5. Navigation lighting

6. Stadium spotlight

7. Industrial lighting

8. High-speed camera lighting

9. Car headlights

Comments

Post a Comment