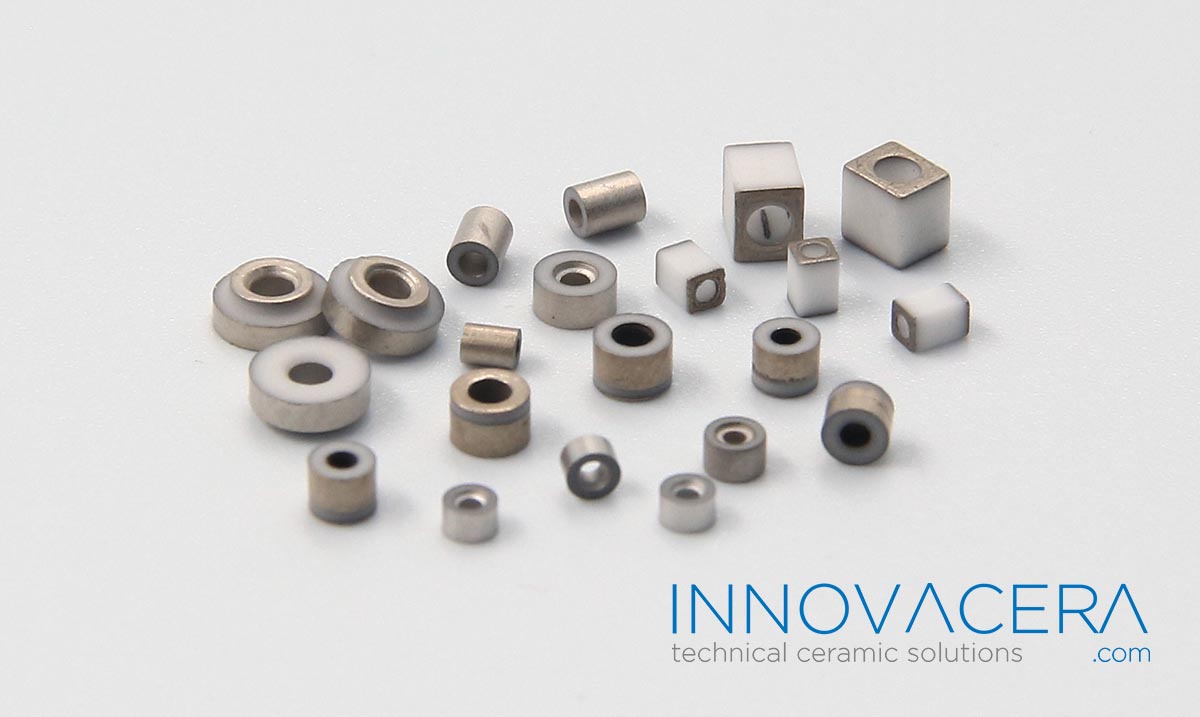

Metallized Ceramic Insulators

INNOVACERA’s metallized ceramic insulators are made by ceramic combined with thick metal films through a metallization process. This combination of ceramic and metal results in insulators that can withstand harsh conditions and provide electrical isolation when needed.

Metallization Spec.:

Molybdenum/Manganese (Mo/Mn) metallization: 9-30um

Ni plating thickness: 3-10um

Metallized Ceramic Insulators Material Properties:

| No | Item | Unit | Value |

| 1 | Purity | % | ≥95 |

| 2 | Volume density | g/cm3 | ≥3.6 |

| 3 | Water absorption | % | 0 |

| 4 | Thermal conductivity | W/m·K( 25℃) | 22.4 |

| 5 | Coefficient of thermal expansion | X(10-6)/℃ (20-1000℃) | 8.2 |

| 6 | Flexural strength | Mpa | 340 |

| 7 | Compressive strength | Mpa | 2103 |

| 8 | Tensile strength | Mpa | 193 |

| 9 | Hardness | ROCKWELL 45N | 78 |

| 10 | Withstand voltage | K Vac/mm | 8.3 |

| 11 | Dielectric constant | @1MHz | 9.1 |

| 12 | Dielectric loss angle | @1MHz | 0.0004 |

| 13 | Volume resistivity | @25℃ | 1×10-14 |

| @500℃ | 4×10-9 | ||

| @1000℃ | 5×105 |

Metallized Ceramic Insulators Features:

1. The ceramic material is with even texture, each batch has stability quality and flexural strength.

2. Metal layer is dense, constant, smooth and good weldability.

3. Excellent electrical insulation, low dielectric constant, good abrasion, and corrosion resistance.

4. High tensile strength, good airtightness to meet the requirement of the high-frequency, high-power and safe electrical components.

Metallized Ceramic Insulators Application:

Semiconductor packaging, TO packaging, Fiber optic device shell, Laser Shell, Vacuum electronic devices, LED accessories etcs.

Comments

Post a Comment