Brief Introduction of Metallization Ceramics

Source: https://www.innovacera.com/news/brief-introduction-of-metallization-ceramics.html

Brief Introduction of Metallization Ceramics

Advanced ceramics are widely used in electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Advanced ceramics have good thermal stability (i.e., a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard and have excellent dimensional stability.

As a result, the list of applications for advanced ceramics is including aerospace engine blades, rings and valve components, industrial pump bearings, cutting tools and die parts, medical instruments, and wide uses in the electronics industry as a substrate and in specialized vacuum components.

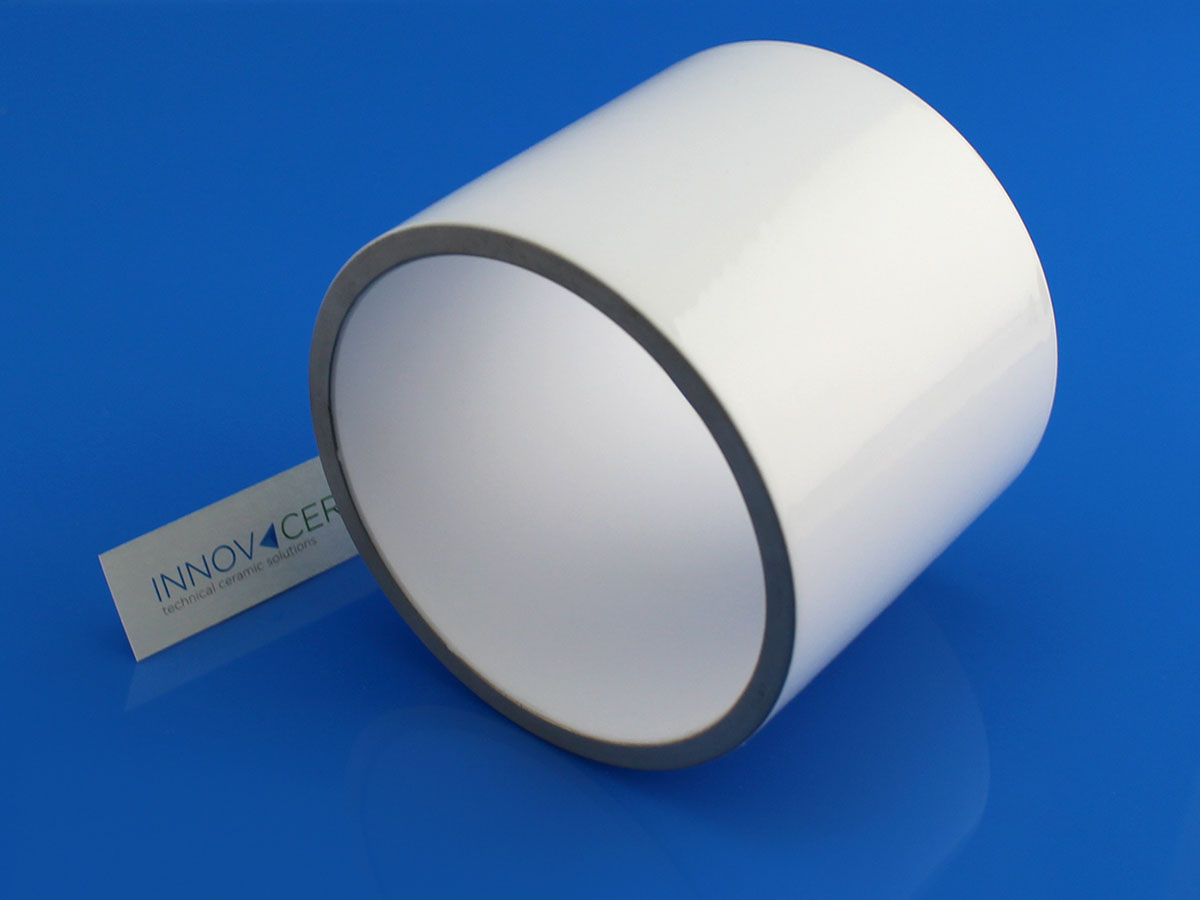

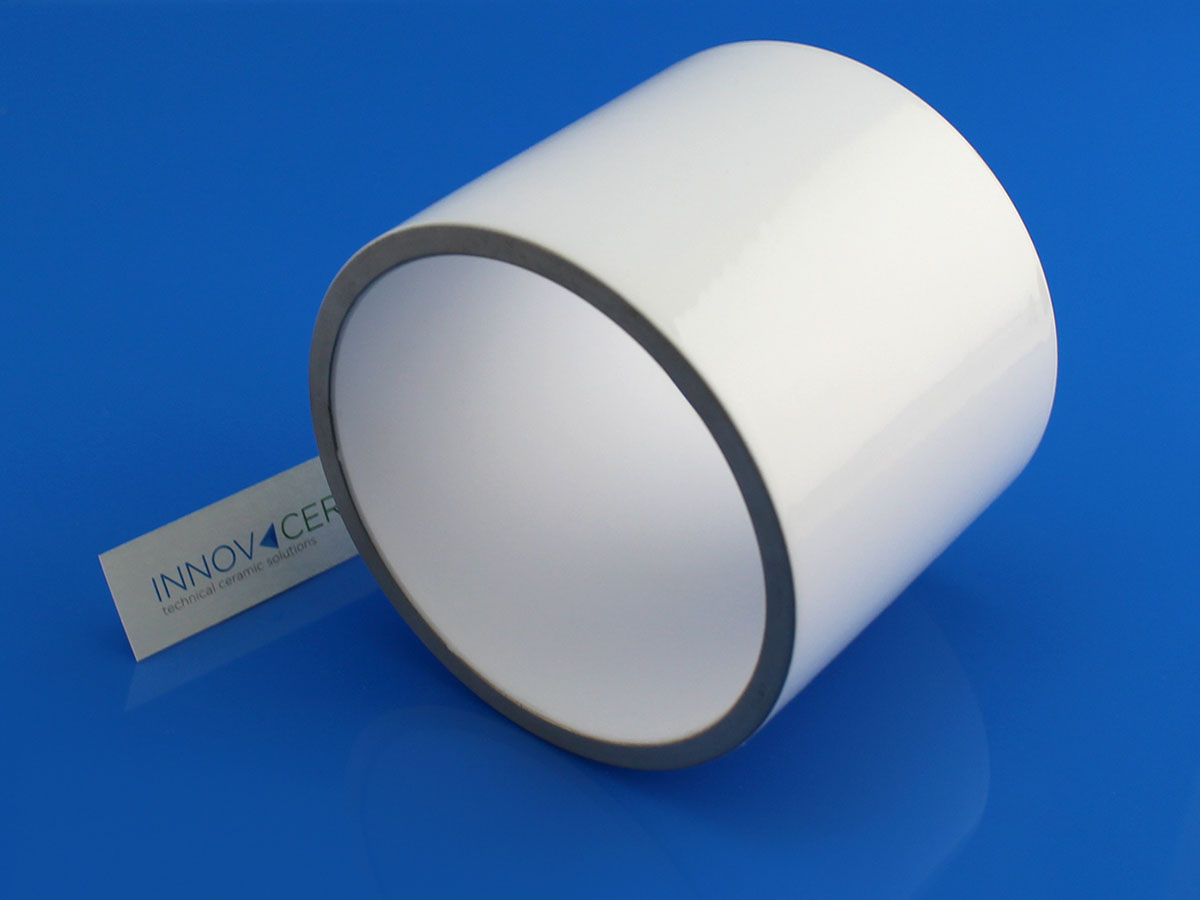

Metallization ceramics is a famous coating technology in advanced ceramics. They are commonly used in many applications, for example, in power electronics components placed under extreme load, electrical drive engineering, and electrical engineering as well as in electronic components for computer technology.

Key Features

Key Features

Brief Introduction of Metallization Ceramics

Advanced ceramics are widely used in electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Advanced ceramics have good thermal stability (i.e., a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard and have excellent dimensional stability.

As a result, the list of applications for advanced ceramics is including aerospace engine blades, rings and valve components, industrial pump bearings, cutting tools and die parts, medical instruments, and wide uses in the electronics industry as a substrate and in specialized vacuum components.

Metallization ceramics is a famous coating technology in advanced ceramics. They are commonly used in many applications, for example, in power electronics components placed under extreme load, electrical drive engineering, and electrical engineering as well as in electronic components for computer technology.

Key Features

Key Features- Standard Moly-Manganese coatings of .001”+/-.0005” offers a uniform coat and optimum peel strength

- Standard Nickel plating thickness of .0001”/.0004” creates an ideal surface for vacuum-tight braze seals

- Superior bare ceramic and metallization quality

- Vertically integrated ceramic processing with traceability from the bare ceramic powder through metallization and Nickel plating

- Application engineering support

- Specialization in prototype to medium volume with the ability to seamlessly upscale to high volume production if required.

- Face metallization of large and small parts

- Pattern screening of highly intricate details

- Complete OD metallization

- Complete ID metallization of even the smallest thru holes

- Counterbore metallization

- ID/OD striping to tight tolerance bandwidths

- Electrolytic and Electroless Nickel plating processes

- RF windows

- Vacuum tubes

- Laser tubes

- X-ray Tubes

- Feedthrough

- Headers

- High-power receptacles

- Insulating discs

- Insulator rings and cylinders

- Precipitator products

- Power switches

- Traveling wave tubes

- Power grid tubes

Comments

Post a Comment