Ultra High Precision Ceramic Ring Gauges Ceramic Setting Ring

Innovacera developed a series of ceramic accessories for Inside Micrometers, Holtest and Dial Bore Gages. The ceramic material used mostly is zirconia.

The zirconia ceramic setting ring advantages:

- High wear resistance and long service life

- The coefficient of thermal expansion is very small, the effect of temperature is very small

- The hardness is very high, there is no need to worry about surface scars.

- Ring gauge management is simple (regular inspection interval is long, saving cost).

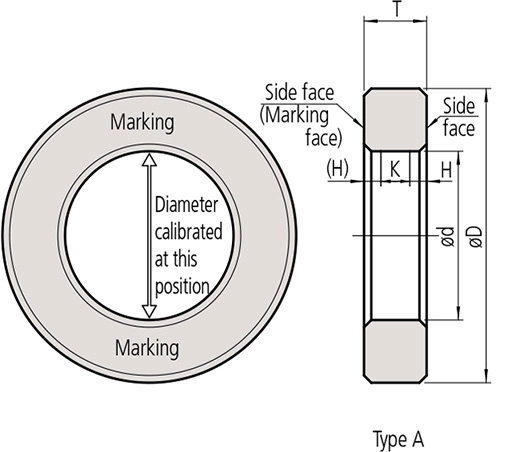

Surface Roughness: Not more than Ra0.1um

Straight Angle: 0.05/φ100

Parallelism: Not more than0.015mm

Each 0.5mm as one size, from 1mm to 50mm.

| Size | Dimensional interval | Roundness | Outer diameter tolerance: | Inner diameter tolerance | Hardness |

| 1-29mm | 0.5mm | 0.5um | ±1um | ±1um | 1200HV |

| 30-50mm | 0.5mm | 0.8um | ±1.6um | ±1.5um | 1200HV |

Some Zirconia Ceramic Ring Gauges Innovacera made and size detail:

9mm, 10mm, 18mm, 20mm, 24mm, 25mm, 28mm

| D(mm) | d(mm) | T(mm) | outer chamfer(mm) | inner chamfer(mm) |

| 1-2 | 22 | 4 | 0.4 | 0.3 |

| 2.5-4.5 | 22 | 5 | 0.4 | 0.3 |

| 5-9.5 | 32 | 8 | 0.8 | 0.5 |

| 10-14.5 | 38 | 10 | 1.2 | 0.5 |

| 15-19.5 | 45 | 12 | 1.2 | 1.0 |

| 20-24.5 | 53 | 14 | 1.2 | 1.0 |

| 25-31.5 | 63 | 16 | 1.5 | 1.0 |

| 32-39.5 | 71 | 18 | 2.0 | 1.0 |

| 40-50 | 85 | 20 | 2.0 | 1.0 |

Comments

Post a Comment